I. Introduction

A. Brief overview of PLC-HMI operational systems in rubber manufacturing equipment

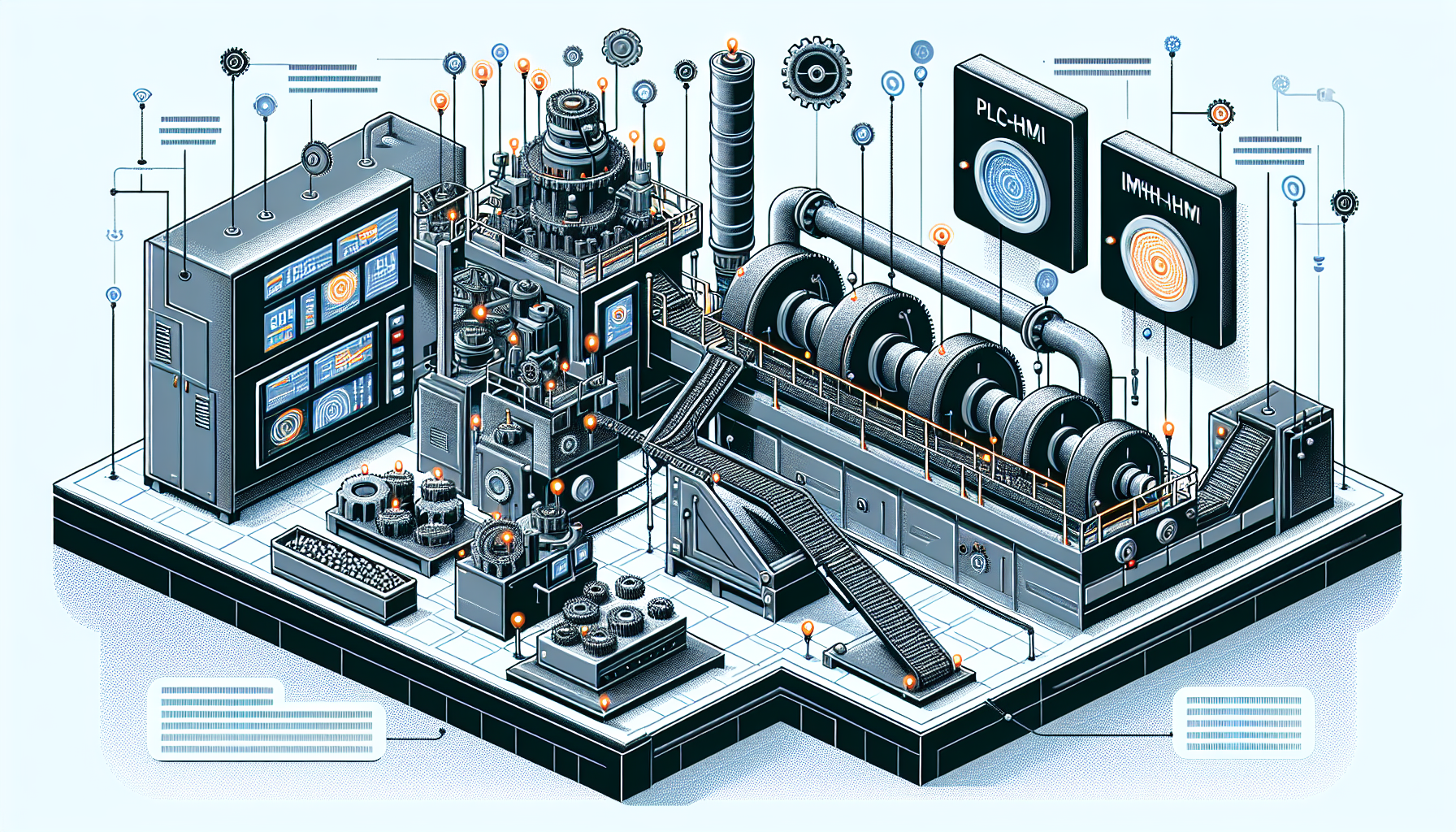

PLC-HMI operational systems play a crucial role in rubber manufacturing equipment, providing automation and control for better efficiency, productivity, and accuracy in the production process.

B. Importance of automation in the rubber industry

Automation significantly impacts the rubber industry, reducing manual labor, enhancing precision and consistency in product quality, and ensuring a safer working environment for operators.

II. Understanding Programmable Logic Controllers (PLCs) in Rubber Manufacturing

Programmable Logic Controllers (PLCs) are essential components in rubber manufacturing equipment, helping automate and control various processes for improved efficiency and productivity. In this section, we will explore how PLCs work in rubber manufacturing equipment, their key features and advantages, and the common applications and industries using PLCs in rubber manufacturing.

A. How PLCs work in rubber manufacturing equipment

PLCs are specialized computers designed to control industrial processes, such as rubber manufacturing. They monitor inputs from sensors and other devices, process the data, and send outputs to control various equipment, like motors and valves. PLCs use a programming language called ladder logic, which is easily understood by engineers and technicians. In rubber manufacturing, PLCs play a crucial role in automating tasks like mixing, extruding, curing, and quality control, ensuring a consistent and efficient production process.

B. Key features and advantages of PLCs in rubber manufacturing

PLCs offer several features and advantages for rubber manufacturing, such as:

- Flexibility: PLCs can be easily programmed and reprogrammed to accommodate changes in the manufacturing process, making them suitable for various rubber products and production methods.

- Reliability: PLCs are designed to withstand harsh industrial environments, ensuring consistent performance and minimal downtime.

- Real-time control: PLCs provide real-time monitoring and control of the manufacturing process, enabling quick adjustments and better quality control.

- Integration with other systems: PLCs can easily integrate with other industrial automation systems, such as Human-Machine Interfaces (HMIs) and Supervisory Control and Data Acquisition (SCADA) systems, for improved process visibility and control.

C. Common applications and industries using PLCs in rubber manufacturing

PLCs are used in various applications and industries in rubber manufacturing, including:

- Tire production: PLCs help control processes like mixing, calendaring, extruding, and vulcanizing in tire manufacturing plants.

- Automotive parts: PLCs are used in the production of rubber automotive components, such as seals, gaskets, and hoses.

- Consumer products: Rubber products like footwear, gloves, and toys also rely on PLC-controlled manufacturing processes.

- Industrial applications: PLCs play a vital role in the manufacturing of rubber parts for machinery, such as belts, seals, and dampers.

- Healthcare industry: Rubber components used in medical devices and equipment, like seals and tubing, are produced with the help of PLCs.

III. Understanding Human-Machine Interfaces (HMIs) in Rubber Manufacturing

Human-Machine Interfaces (HMIs) are essential components in rubber manufacturing equipment, enabling operators to interact with and control various processes. In this section, we will explore how HMIs work in rubber manufacturing equipment, their key features and advantages, and the common applications and industries using HMIs in rubber manufacturing.

A. How HMIs work in rubber manufacturing equipment: user interfaces, connectivity, etc.

HMIs serve as the bridge between operators and the manufacturing process, providing a user-friendly interface for monitoring, controlling, and adjusting equipment settings. They typically comprise touchscreens, keyboards, or a combination of both, allowing for easy interaction with the Programmable Logic Controllers (PLCs) that control the manufacturing processes. HMIs connect with PLCs and other industrial automation systems through various communication protocols, such as Ethernet, Modbus, or CANopen, ensuring seamless integration and data exchange.

B. Key features and advantages of HMIs in rubber manufacturing

HMIs offer several features and advantages for rubber manufacturing, such as:

- Intuitive operation: HMIs provide a user-friendly interface, allowing operators to quickly learn and manage the manufacturing process, even with limited technical knowledge.

- Real-time monitoring: HMIs enable operators to monitor the manufacturing process in real-time, making it easier to identify and address issues promptly.

- Enhanced productivity: By simplifying process control and providing real-time feedback, HMIs help operators optimize production, reducing waste and downtime.

- Customizability: HMIs can be customized to suit specific rubber manufacturing processes, ensuring a tailored solution that meets the unique needs of each application.

- Improved safety: HMIs can include safety features like alarms, interlocks, and emergency stop functions, helping to prevent accidents and protect operators.

C. Common applications and industries using HMIs in rubber manufacturing

HMIs are used in various applications and industries in rubber manufacturing, including:

- Tire production: HMIs enable operators to monitor and control processes like mixing, calendaring, extruding, and vulcanizing in tire manufacturing plants.

- Automotive parts: HMIs are used in the production of rubber automotive components, such as seals, gaskets, and hoses, helping to ensure quality and consistency.

- Consumer products: HMIs play a key role in the manufacturing of rubber products like footwear, gloves, and toys, providing operators with an intuitive interface for process control.

- Industrial applications: HMIs are used in the manufacturing of rubber parts for machinery, such as belts, seals, and dampers, ensuring optimal production efficiency and quality.

- Healthcare industry: Rubber components used in medical devices and equipment, like seals and tubing, are produced with the help of HMIs, ensuring precise control and consistency in the manufacturing process.

IV. Benefits of Using PLC-HMI Operational Systems in Rubber Manufacturing Equipment

Integrating PLC-HMI operational systems in rubber manufacturing equipment brings a multitude of benefits that directly impact the efficiency, productivity, and overall performance of the production process. In this section, we will explore four key benefits of using PLC-HMI operational systems in rubber manufacturing equipment.

A. Improved product quality and consistency

One of the primary advantages of using PLC-HMI operational systems in rubber manufacturing is the enhancement of product quality and consistency. PLCs ensure precise control over various manufacturing processes, while HMIs provide real-time monitoring, enabling operators to quickly identify and address any issues or deviations from the desired product specifications. This results in high-quality rubber products that meet or exceed industry standards and customer expectations.

B. Efficient and energy-saving operation

Efficiency is a critical factor in the rubber manufacturing industry, and PLC-HMI operational systems contribute significantly to this aspect. By automating and optimizing the production process, these systems help reduce waste, minimize downtime, and lower energy consumption. This not only cuts operational costs but also contributes to a more sustainable and eco-friendly manufacturing process.

C. Versatility and wide range of applications

PLC-HMI operational systems offer remarkable versatility in terms of their applicability across various rubber manufacturing processes and industries. Their flexibility, customizability, and adaptability make them suitable for producing a wide range of rubber products, from tires and automotive components to consumer goods and medical devices. This broad applicability ensures that rubber manufacturing companies can leverage PLC-HMI operational systems to cater to diverse market demands and requirements.

D. Easy operation and maintenance

PLC-HMI operational systems are designed to simplify the operation and maintenance of rubber manufacturing equipment. The intuitive interface of HMIs enables operators to monitor and control the production process with ease, even with limited technical knowledge. Furthermore, PLCs are built to withstand harsh industrial environments, ensuring consistent performance and minimal downtime. This ease of operation and maintenance not only helps improve the overall efficiency of the manufacturing process but also reduces the burden on operators and maintenance personnel.

V. Microquick Engineers’ Hydraulic Dispersion Kneaders with PLC-HMI Control Systems

Microquick Engineers, a leading manufacturer of hydraulic dispersion kneaders, leverages over 25 years of experience in the industry to deliver innovative and high-quality rubber manufacturing equipment. Their hydraulic dispersion kneaders are equipped with advanced PLC-HMI control systems, providing numerous benefits for various industries and applications.

A. Over 25 years of experience in the industry

Microquick Engineers has built a solid reputation in the rubber manufacturing industry, combining their extensive experience and technical expertise to develop and produce state-of-the-art hydraulic dispersion kneaders that meet the diverse needs of their customers.

B. Key features of Microquick Engineers’ Hydraulic Dispersion Kneaders

Microquick Engineers’ hydraulic dispersion kneaders boast a range of features that make them stand out in the market:

- Automated continuous hydraulic compression on ingredients

- Batch preparation time of 7-12 minutes

- Excellent dispersion of ingredients

- Consistent quality compounding

- Convenient production of hard batches

- Wear resistance of mixing chamber and rotors

- Innovative shaft seals with lubrication passage to prevent ingredient leaks

- Low energy consumption

C. Unique selling points of Microquick Engineers’ PLC-HMI control systems

Microquick Engineers’ PLC-HMI control systems offer several unique selling points that set them apart from competitors:

- Excellent quality compounding

- Faster production

- Automated and consistent batch preparation

- Value for investment

- Good performance for stop leak and fly of ingredients

- Operator-friendly design

- Compact size

D. Applications of Hydraulic Dispersion Kneaders with PLC-HMI Control Systems in various industries

The advanced features and benefits of Microquick Engineers’ hydraulic dispersion kneaders with PLC-HMI control systems make them suitable for a wide range of industries and applications, including:

- Automotive industry: Rubber components for vehicles, such as seals, gaskets, and hoses

- Industrial applications: Rubber parts for machinery, like belts, seals, and dampers

- Consumer products: Rubber goods, such as footwear, gloves, and toys

- Healthcare industry: Rubber components for medical devices and equipment, like seals and tubing

- Electrical industry: Insulation materials and other rubber-based electrical components

VI. Choosing the Right Rubber Manufacturing Equipment with PLC-HMI Operational Systems

When selecting the ideal rubber manufacturing equipment with PLC-HMI operational systems, it is crucial to make informed decisions that consider various factors, weigh the advantages of using a PLC, HMI, or both, and select the right HMI systems supplier. In this section, we will explore these aspects to help you make the best choice for your rubber manufacturing needs.

A. Factors to consider when deciding between a PLC and HMI

In order to determine the most suitable solution for your rubber manufacturing equipment, consider factors such as:

- The complexity of the manufacturing process: PLCs are better suited for complex processes that require precise control, while HMIs are ideal for simpler processes with minimal control requirements.

- Integration with existing systems: Ensure that the chosen PLC or HMI can seamlessly integrate with your current industrial automation systems.

- Customizability: Evaluate the extent to which the PLC or HMI can be customized to suit your specific rubber manufacturing processes and requirements.

- Cost-effectiveness: Assess the overall cost of implementing a PLC or HMI solution, including hardware, software, and maintenance expenses, and compare it with the expected benefits and return on investment.

B. Guidance on when to use a PLC, HMI, or both

Here are some general guidelines to help you decide whether to use a PLC, HMI, or both in your rubber manufacturing equipment:

- For complex processes that require precise control and real-time monitoring, a combination of PLC and HMI systems is recommended.

- If the manufacturing process is relatively simple and only requires basic control functions, an HMI system might be sufficient.

- In cases where the rubber manufacturing process is highly complex and involves multiple control loops, a PLC system alone may be the most suitable solution.

C. Choosing the proper HMI systems supplier

Lastly, selecting the right HMI systems supplier is crucial to ensure a reliable and high-quality solution for your rubber manufacturing equipment. Consider the following factors when evaluating potential suppliers:

- Industry experience: Choose a supplier with extensive experience in providing HMI systems for rubber manufacturing or similar industries.

- Technical expertise: Ensure that the supplier has the necessary technical knowledge and resources to design, implement, and support the HMI solution.

- Product range: Evaluate the supplier’s range of HMI products and solutions, ensuring that they offer options that can cater to your specific requirements.

- Customer support: Assess the supplier’s customer service and support capabilities, ensuring that they can provide prompt and efficient assistance when needed.

- Reputation: Check the supplier’s reputation in the industry, including customer testimonials and reviews, to gauge their reliability and track record of success.

By considering these factors and guidelines, you can make an informed decision when choosing the right rubber manufacturing equipment with PLC-HMI operational systems, ensuring a solution that meets your specific requirements and delivers optimal performance and productivity.

VII. Conclusion

In conclusion, PLC-HMI operational systems play a crucial role in rubber manufacturing equipment, offering numerous benefits that enhance the efficiency, productivity, and overall performance of the production process. Throughout this article, we have explored the benefits of PLC-HMI operational systems, such as improved product quality and consistency, efficient and energy-saving operation, versatility and wide range of applications, and easy operation and maintenance. The use of advanced technology, such as that offered by Microquick Engineers’ hydraulic dispersion kneaders with PLC-HMI control systems, is essential for rubber manufacturers to remain competitive in the industry.

Investing in advanced technology for rubber manufacturing is not only a smart business decision but also a necessity for companies to meet the ever-evolving market demands and stay ahead in the industry. By understanding the benefits and importance of PLC-HMI operational systems, rubber manufacturers can make informed decisions in selecting the right equipment and technology to optimize their production processes and ultimately achieve greater success in their business endeavors.

Discover Advanced Solutions

Enhance your rubber manufacturing processes with Microquick Engineers’ state-of-the-art hydraulic dispersion kneaders featuring PLC-HMI operational systems. Experience the numerous benefits and elevate your production efficiency, product quality, and overall performance.

-

A. Download Microquick Engineers’ brochure for more information on their products and services

Learn more about the advanced features and unique selling points of Microquick’s Hydraulic Dispersion Kneaders. Download their brochure at https://microquick.us/brochure and explore their innovative solutions for your rubber manufacturing needs.

-

B. Contact Microquick Engineers for inquiries and support in Tampa, USA, and Ahmedabad, India

Microquick Engineers is here to support you every step of the way. Reach out to them for inquiries or assistance at https://microquick.us/contact . Their team of experts is ready to help you make the most of their cutting-edge hydraulic dispersion kneaders and PLC-HMI operational systems.