Rubber compounding machines play a crucial role in various industries, providing efficient and consistent compounding of rubber materials. Whether it’s in the automotive, industrial, consumer products, healthcare, electrical, or other rubber industries, the need for high-quality rubber compounds is undeniable.

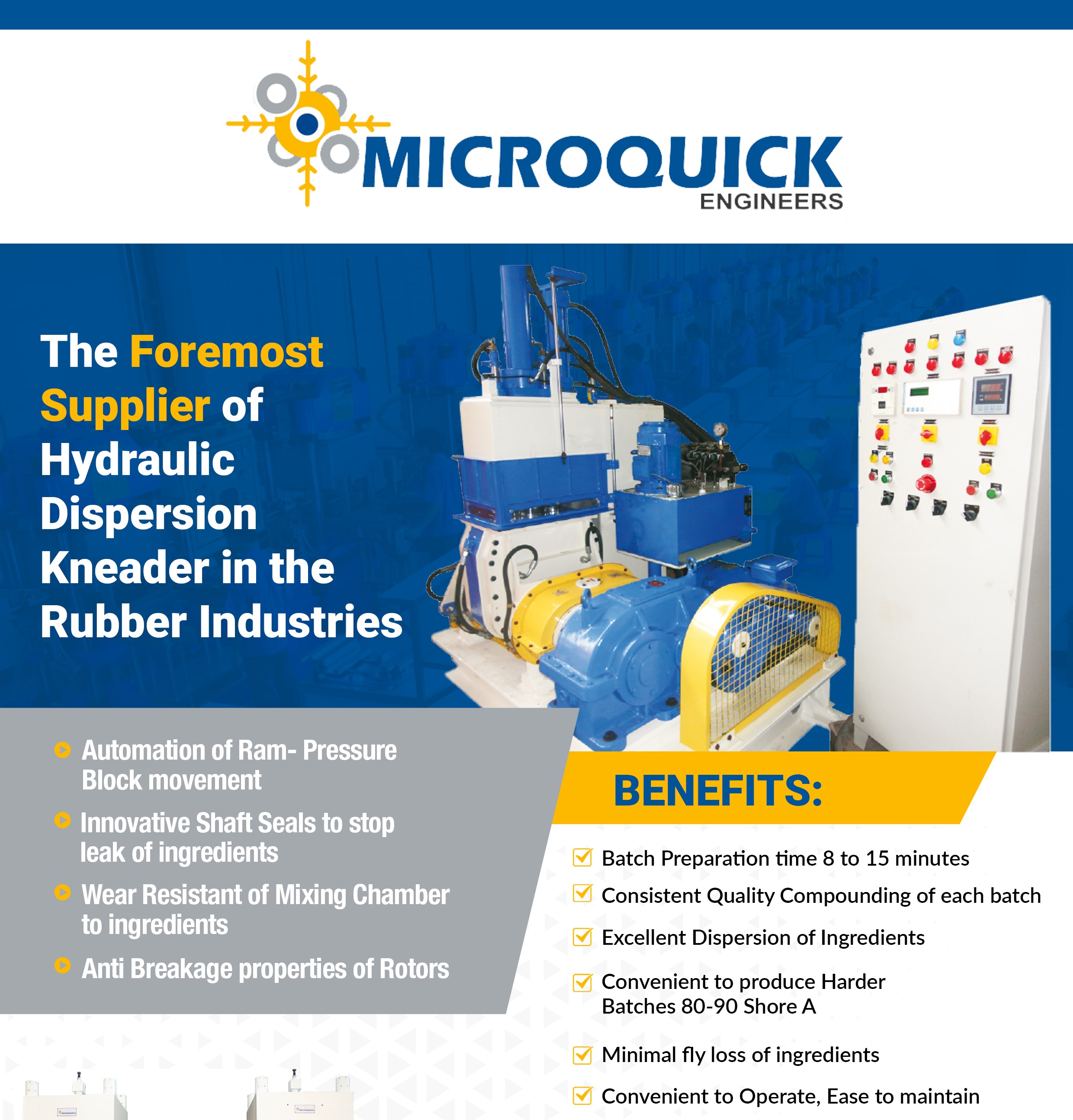

Introducing Microquick Engineers

With over 25 years of experience, Microquick Engineers is a leading manufacturer and exporter of Hydraulic Dispersion Kneaders. These machines are designed to offer excellent compounding performance, with automated continuous hydraulic ram pressure on ingredients. The result? Efficient production with batch preparation times ranging from 7-12 minutes.

But it’s not just about speed. The kneaders from Microquick Engineers also ensure excellent dispersion of ingredients and consistent quality compounding. The mixing chamber and rotors are wear-resistant, guaranteeing durability. Plus, these machines have low energy consumption, contributing to sustainability.

Optimize Your Rubber Compounding Process

If you’re looking to optimize the performance and efficiency of your rubber compounding process, Microquick Engineers has got you covered. Check out their website for more information and explore their video library showcasing their products. And don’t forget to read their informative blog posts on enhancing automotive rubber parts quality, energy efficiency in rubber processing equipment, and tips for choosing the right hydraulic dispersion kneader manufacturer.

Start Exploring Today

Discover the difference that rubber compounding machines can make in your industry. Start by exploring Microquick Engineers’ range of Hydraulic Dispersion Kneaders today.

Understanding Rubber Compounding

In the world of rubber manufacturing, rubber compounding plays a crucial role in creating high-quality rubber products. This process involves blending various ingredients to achieve the desired properties and performance of the final rubber compound. Let’s dive deeper into the definition, purpose, and key ingredients used in rubber compounding.

Definition and Purpose of Rubber Compounding

Rubber compounding is the process of mixing and blending different ingredients to create a rubber compound with specific characteristics. The purpose of rubber compounding is to enhance the properties of raw rubber, such as flexibility, durability, and resistance to heat, chemicals, and wear. By carefully selecting and combining different ingredients, rubber compounders can tailor the final product to meet the specific requirements of various industries, including automotive, industrial, consumer products, healthcare, electrical, and others.

Key Ingredients Used in Rubber Compounding

Rubber compounding involves the use of several key ingredients, each playing a unique role in the final compound. These ingredients include:

-

Base Polymers:

The base polymers are the primary raw materials in rubber compounding. Natural rubber (NR) and synthetic rubbers, such as styrene-butadiene rubber (SBR) and butadiene rubber (BR), are commonly used as base polymers. These polymers provide the desired elasticity and strength to the rubber compound. -

Fillers:

Fillers, such as carbon black and silica, are added to improve the mechanical properties of the rubber compound. They enhance the compound’s strength, abrasion resistance, and tear resistance. Fillers also help reduce costs and improve the processability of the compound. -

Plasticizers:

Plasticizers, such as oils and resins, are used to improve the flexibility and processability of the rubber compound. They help reduce the stiffness of the compound, making it easier to mix and shape during the manufacturing process. -

Vulcanizing Agents:

Vulcanizing agents, such as sulfur and peroxides, are added to promote cross-linking between polymer chains. This cross-linking process, known as vulcanization, gives the rubber compound its desired strength, elasticity, and heat resistance. -

Antioxidants and Antiozonants:

These ingredients protect the rubber compound from degradation caused by oxygen and ozone exposure. They help extend the lifespan of rubber products by preventing cracking, aging, and deterioration.

Importance of Achieving Proper Dispersion and Mixing of Ingredients

One of the critical aspects of rubber compounding is achieving proper dispersion and mixing of the ingredients. This ensures that each ingredient is evenly distributed throughout the compound, resulting in consistent quality and performance. Improper dispersion can lead to variations in properties, such as uneven strength, poor abrasion resistance, and reduced durability.

To achieve proper dispersion, rubber compounders employ various mixing techniques, including mechanical mixing, such as using dispersion kneaders. Microquick Engineers, a leading manufacturer and exporter of Hydraulic Dispersion Kneaders, offers advanced machinery that ensures excellent dispersion and mixing performance. Their hydraulic kneaders apply

continuous hydraulic ram

pressure on ingredients, resulting in efficient production with batch preparation times ranging from 7-12 minutes.

Common Challenges Faced in the Rubber Compounding Process

Rubber compounding is a complex process that comes with its fair share of challenges. Some common challenges include:

-

Ingredient Compatibility:

Different ingredients may have varying compatibility levels, making it challenging to achieve the desired compound properties. Rubber compounders need to carefully select and test ingredients to ensure compatibility and avoid undesirable reactions. -

Dispersion Issues:

Achieving proper dispersion can be challenging, especially when dealing with high filler loadings or complex formulations. Inadequate dispersion can result in poor compound performance and inconsistencies in the final product. -

Batch-to-Batch Consistency:

Maintaining consistent compound properties across different batches is crucial for ensuring product quality. Any variations in the compounding process can lead to inconsistencies and affect the performance of the final rubber products.

By understanding the definition, purpose, and key ingredients of rubber compounding, as well as the challenges involved, we can appreciate the complexity and importance of this process in the rubber manufacturing industry. With the right equipment and expertise, companies like Microquick Engineers are revolutionizing rubber compounding, offering efficient solutions that ensure excellent dispersion, consistent quality, and improved productivity.

Types of Rubber Compounding Machines

Rubber compounding machines are essential in the rubber manufacturing industry as they play a crucial role in achieving the desired properties and characteristics of rubber compounds. There are several types of rubber compounding machines available, each with its own unique features and functionalities. In this section, we will explore the different types of rubber compounding machines and discuss their advantages and applications.

Rubber Kneader

One of the most commonly used rubber compounding machines is the rubber kneader. A rubber kneader is a machine that uses a hydraulic ram to continuously apply pressure on the ingredients, resulting in excellent compounding performance. Microquick Engineers, a leading manufacturer and exporter

of hydraulic dispersion kneaders

, offers a range of kneaders with batch preparation times ranging from 7 to 12 minutes, ensuring efficient production.

The advantages of using a rubber kneader include its ability to provide

excellent dispersion of ingredients

and consistent quality compounding

. This is crucial in industries such as automotive, industrial, consumer products, healthcare, electrical, and other rubber industries, where precise and consistent rubber compounds are required. The mixing chamber and rotors of Microquick Engineers’ kneaders are designed with wear resistance properties, ensuring durability and long-term performance.

Energy efficiency is another important factor to consider when choosing

a rubber compounding machine

. Microquick Engineers’ kneaders

have low energy consumption

, contributing to sustainability and cost savings for manufacturers. With over 25 years of experience in the industry and a high customer satisfaction rate, Microquick Engineers is a trusted choice for rubber compounding machines.

Rubber Mixers

When comparing rubber kneaders to other types of rubber compounding machines, such as rubber mixers, it’s important to consider the specific requirements of your application. Rubber mixers, also known as internal mixers, use a different mixing mechanism compared to kneaders. They typically have rotating blades or rotors that shear

and mix the rubber compounds

.

Rubber mixers are known for their ability to handle large volumes of rubber compounds and are often used in high-volume production settings. However, they may not offer the same level of dispersion and consistency as rubber kneaders. It’s important to evaluate the specific needs of your application and consult with experts, such as Microquick Engineers, to determine the most suitable type of rubber compounding machine for your requirements.

There are different types of rubber compounding machines available, each with its own advantages and applications. Rubber kneaders, such as the ones offered by Microquick Engineers, provide excellent compounding performance, dispersion of ingredients, and consistent quality compounding. On the other hand, rubber mixers offer high-volume production capabilities but may have limitations in terms of dispersion and consistency. It’s essential to carefully evaluate your specific requirements and consult with industry experts to choose the most suitable rubber compounding machine for your needs. Remember, the right machine can make all the difference in achieving optimal rubber compound properties and ensuring efficient production.

Durability and Wear Resistance Properties of Rubber Compounding Machines

When choosing

a rubber compounding machine

, one

of the key factors to consider

is its durability and wear resistance properties. This is essential because the machine will be subjected to rigorous use and must be able to withstand the demands of the compounding process.

Microquick Engineers, a leading manufacturer and exporter

of hydraulic dispersion kneaders

, understands the importance of durability in their machines. Their kneaders are specifically designed to provide long-lasting performance, even in the most demanding environments.

The mixing chamber and rotors of Microquick Engineers’ hydraulic dispersion kneaders are built with wear resistance properties. This means that they are highly resistant to the wear and tear that occurs during the compounding process. As a result, the machines maintain their efficiency and performance over an extended period of time, reducing the need for frequent maintenance or replacement.

By investing in a durable rubber compounding machine, businesses can significantly reduce downtime and increase productivity. A machine that can withstand the demands of continuous operation without compromising on performance ensures smooth and uninterrupted compounding processes.

In addition to durability, wear resistance properties are also crucial in maintaining consistent compounding quality. When the mixing chamber and rotors of a machine wear out, it can lead to uneven dispersion of ingredients and compromised product quality. Microquick Engineers’ kneaders provide

excellent dispersion of ingredients

, ensuring consistent and high-quality compounding results.

Not only does the durability

and wear resistance of a rubber

compounding machine impact its performance, but it also contributes to the overall cost-effectiveness of the operation. Machines that require frequent repairs or replacement parts can significantly increase maintenance costs and downtime. On the other hand, a durable machine with wear resistance properties minimizes these expenses, allowing businesses to maximize their production efficiency and profitability.

Microquick Engineers

has over 25 years of experience

in the industry, and their high

customer satisfaction rate

is a testament to the quality and durability of their products. Through their video library and positive testimonials from satisfied customers, they showcase the performance and longevity of their hydraulic dispersion kneaders.

When considering a rubber compounding machine, it is essential to prioritize durability and wear resistance properties. By choosing a machine that is built to withstand the demands of the compounding process, businesses can ensure consistent performance, reduce maintenance costs, and maximize productivity. Microquick Engineers’ hydraulic dispersion kneaders offer the durability and wear resistance properties necessary for efficient and reliable compounding operations.

For more information on Microquick Engineers’ hydraulic dispersion kneaders and their range of products, visit their website at [CTA1]. Additionally, their blog posts

on optimizing performance and efficiency

[CTA2], enhancing

automotive rubber parts

quality [CTA3], and the importance of energy efficiency in rubber processing equipment [CTA4] provide valuable insights into the rubber compounding industry.

Troubleshooting Common Issues with Rubber Compounding Machines

When operating rubber compounding machines, it is important to be prepared for any potential issues that may arise. Troubleshooting common problems can save time, reduce downtime, and ensure the smooth operation of the machine. In this section, we will discuss some common issues that may occur with rubber compounding machines and provide tips for troubleshooting them effectively.

-

Uneven Mixing

One of the most common issues in rubber compounding is uneven mixing. This can result in variations in the quality and performance of the final product. To troubleshoot this issue, start by checking the alignment of the mixing chamber and the rotors. Misalignment can cause uneven mixing. Adjusting the alignment can help improve the mixing efficiency.

-

Material Build-up

Over time, material can build up on the rotors, mixing chamber, and other parts of the machine. This can affect the machine’s performance and lead to poor mixing results. Regular cleaning and maintenance are essential to prevent material build-up. Follow the manufacturer’s recommended cleaning procedures and use appropriate cleaning agents to remove any residues or build-up.

-

Excessive Heat

Excessive heat can negatively impact the quality of the compound and the overall performance of the machine. If you notice excessive heat during operation, check the cooling system of the machine. Ensure that the cooling water flow is adequate and that there are no blockages in the cooling channels. Additionally, monitor the temperature of the compound during mixing and adjust the parameters accordingly to maintain optimal temperature conditions.

-

Inconsistent Feed Rate

Inconsistent feed rate can lead to variations in the compound’s composition and properties. If you are experiencing issues with the feed rate, check the feed hopper and the feeding mechanism for any blockages or malfunctions. Ensure that the feed material is properly prepared and free from any clumps or impurities that may cause uneven feeding.

-

Abnormal Noise or Vibrations

Unusual noise or vibrations during operation can indicate mechanical issues with the machine. It is important to address these issues promptly to prevent further damage. Inspect the machine for loose or worn-out parts, such as belts, bearings, or gears. Replace any damaged parts and ensure that all components are properly lubricated to minimize friction and reduce noise.

Remember, proper machine setup, regular maintenance, and adherence to safety precautions can significantly reduce the occurrence of common issues with rubber compounding machines. If you encounter any problems that cannot be resolved through troubleshooting, it is recommended to consult the manufacturer’s technical support or a qualified technician for assistance.

By understanding and effectively troubleshooting these common issues, you can ensure the efficient and reliable operation

of your rubber compounding machine

, resulting in high-quality compounds and improved productivity.

For more information on rubber compounding machines and related topics, visit our website at microquick.us . We also have informative blog posts, such as “10 Tips for Optimizing Performance and Efficiency of Your Dispersion Mixer” and “Why Energy Efficiency Matters in Rubber Processing Equipment,” that provide further insights into the industry.

Rubber Compounding Machines: Key Applications and Benefits

Rubber compounding machines have a wide range of applications across various industries. In this section, we will explore some of the key applications of these machines and how they contribute to the production of high-quality rubber products.

Automotive Industry

The automotive industry heavily relies on rubber compounding machines for the production of various components such as tires, seals, gaskets, and hoses. These components require specific rubber formulations to meet the unique performance requirements of the automotive industry. Rubber compounding machines play a crucial role in achieving these formulations by efficiently mixing and blending different ingredients. For example, hydraulic dispersion kneaders offered by Microquick Engineers are designed to provide excellent compounding performance. These machines ensure thorough mixing and dispersion of the rubber compounds, resulting in consistent quality compounding for reliable automotive rubber parts.

Industrial Applications

Industries such as construction, mining, and manufacturing benefit from the use of rubber compounding machines. Rubber compounds are used for various applications including conveyor belts, seals, and vibration dampening materials. These applications require rubber compounds with specific properties such as durability, resistance to chemicals, and flexibility. Rubber compounding machines enable precise control over the mixing process , allowing manufacturers to tailor the rubber compounds to meet these specific requirements.

Consumer Products

Rubber compounds produced using compounding machines are used in a wide range of consumer products. From household items like rubber gloves and footwear to sporting goods like balls and mats, rubber compounds are versatile materials. Manufacturers can produce rubber compounds with different properties, colors, and textures to meet the diverse needs of consumers.

Healthcare and Medical Industry

The healthcare and medical industry relies on rubber compounding machines for the production of medical devices and equipment. Rubber compounds are used in applications such as medical tubing, gloves, and seals. These applications require strict adherence to quality standards and regulations. Rubber compounding machines with excellent dispersion capabilities and consistent performance contribute to the production of high-quality medical rubber products.

Electrical Industry

The electrical industry uses rubber compounding machines for the production of electrical insulation materials, cables, and connectors. These applications require rubber compounds with excellent electrical insulation properties and resistance to heat and chemicals. Rubber compounding machines enable manufacturers to achieve precise control over the compounding process, ensuring the desired electrical properties of the rubber compounds.

Other Rubber Industries

In addition to the key industries mentioned above, rubber compounding machines find applications in other rubber industries such as rubber flooring, rubber rollers, rubber seals, and various rubber molded products. The versatility and efficiency of rubber compounding machines make them suitable for a wide range of rubber processing applications.

In conclusion, rubber compounding machines have diverse applications across industries such as automotive, industrial, consumer products, healthcare, electrical, and other rubber industries. These machines enable manufacturers to produce high-quality rubber compounds with specific properties, contributing to the production of reliable and durable rubber products. Whether it’s automotive components, industrial applications, or consumer products, rubber compounding machines play a crucial role in meeting the unique requirements of each industry.

Innovative Rubber Compounding Machines by Microquick Engineers

Rubber compounding machines are vital in various industries, enabling efficient production and maintaining consistent quality compounding . Microquick Engineers is a renowned manufacturer and exporter of Hydraulic Dispersion Kneaders, offering exceptional compounding performance with automated continuous hydraulic ram pressure on ingredients.

Batch preparation times for Microquick Engineers’ kneaders range from 7 to 12 minutes, contributing to efficient production. The mixing chamber and rotors of these kneaders have wear resistance properties, ensuring durability and longevity. Additionally, they have low energy consumption , promoting sustainability in rubber processing equipment.

With over 25 years of experience in the industry and a high customer satisfaction rate , Microquick Engineers has established itself as a trusted provider of rubber compounding machines. The positive testimonials from satisfied customers speak to their dedication to quality and customer satisfaction.

To learn more about Microquick Engineers’ products and enhance your knowledge of rubber compounding, visit their website. Their video library showcases their products, and their informative blog posts provide valuable insights and tips for professionals in the hydraulic dispersion kneader industry. Some recommended blog posts include:

- 10 Tips for Optimizing Performance and Efficiency of Your Dispersion Mixer

- 7 Tips to Enhance Your Automotive Rubber Parts Quality

- Why Energy Efficiency Matters in Rubber Processing Equipment

Staying updated with the latest advancements and best practices in rubber compounding is crucial for achieving optimal results. Visit Microquick Engineers’ website and blog to stay informed and enhance your expertise in this field. Together, we can drive innovation and efficiency in rubber compounding processes.

To explore Microquick Engineers’ products and learn more, visit their website .