In the fast-paced world of manufacturing, efficiency is key. Every minute wasted in production can translate to lost profits and missed opportunities. That’s why it’s crucial to invest in equipment that can maximize productivity and streamline processes. One such equipment that has been revolutionizing the industry is the Hydraulic Dispersion Kneader.

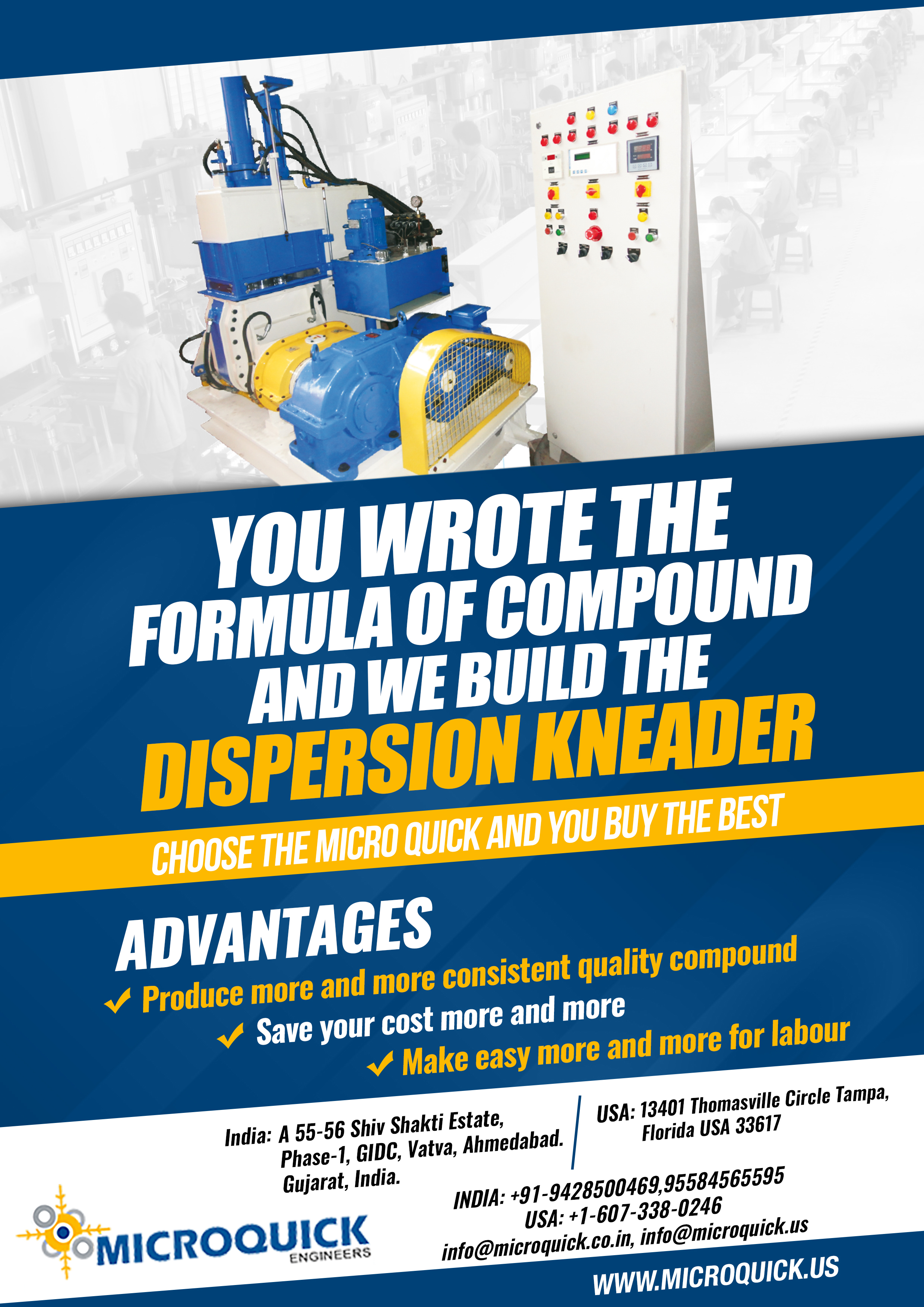

Hydraulic Dispersion Kneaders, offered by Microquick Engineers, are designed to deliver industry-leading performance and excellent compounding results. With automated continuous hydraulic ram pressure on ingredients, these kneaders can significantly reduce batch preparation times, ranging from 7 to 12 minutes. This means faster production and more output within a shorter timeframe.

But it’s not just about speed. These kneaders also excel in achieving excellent dispersion of ingredients and consistent quality compounding . The mixing chamber and rotors are built with wear resistance properties, ensuring durability even in demanding production environments. Innovative shaft seals with lubrication passage prevent ingredient leakage, further enhancing operational convenience.

Whether you’re in the automotive, industrial, consumer products, healthcare, electrical, or rubber industries, Hydraulic Dispersion Kneaders can cater to your needs. Their low energy consumption makes them an energy-efficient choice for any production facility.

With over 25 years of experience in the industry, Microquick Engineers has gained a reputation for delivering high-quality equipment that meets customer satisfaction. So why settle for less when you can maximize your productivity with Hydraulic Dispersion Kneaders?

In the next sections, we will explore the features and benefits of these kneaders in more detail. Stay tuned to discover how you can take your production to the next level.

The Benefits of Hydraulic Dispersion Kneaders

In today’s fast-paced and competitive industries, productivity plays a crucial role in determining the success and profitability of businesses. The ability to efficiently produce high-quality products in a timely manner can give companies a significant edge over their competitors. That’s where Hydraulic Dispersion Kneaders come into play. These innovative machines are designed to enhance productivity and streamline the compounding process, making them an essential tool for various industries.

Enhanced Productivity

- Hydraulic Dispersion Kneaders are specifically engineered to mix and compound materials effectively and efficiently.

- They utilize automated continuous hydraulic ram pressure on ingredients, resulting in batch preparation times of just 7-12 minutes.

- Manufacturers can produce more output in less time, leading to increased productivity and faster turnaround.

- With rapid processing capabilities, businesses can meet customer demands and stay ahead in the market.

Consistent Quality Compounding

One of the key benefits of using Hydraulic Dispersion Kneaders is their ability to provide excellent dispersion of ingredients

and consistent quality compounding

. The mixing chamber and rotors of these machines are designed with wear resistance properties, ensuring durability and long-term performance. Additionally, the innovative shaft seals with lubrication passage prevent ingredient leakage, further enhancing the efficiency and effectiveness of the compounding process.

Operational Convenience and Energy Efficiency

The benefits of using Hydraulic Dispersion Kneaders extend beyond improved productivity and quality. These machines also offer operational convenience

and low energy consumption

, making them suitable for a wide range of industries. Whether it’s automotive, industrial, consumer products, healthcare, electrical, or other rubber industries, Hydraulic Dispersion Kneaders can significantly enhance the compounding process and drive overall efficiency.

About Microquick Engineers

Microquick Engineers, a leading manufacturer and exporter of Hydraulic Dispersion Kneaders,

has over 25 years of experience

in the industry. Their kneaders are known for their industry-leading performance and excellent compounding results. With a high customer satisfaction rate, Microquick Engineers has established itself as a trusted provider of innovative solutions for enhanced productivity.

Learn More

To learn more about Hydraulic Dispersion Kneaders and how they can revolutionize your compounding process, visit Microquick Engineers’ website at microquick.us . You can also explore their blog for valuable tips and insights

on optimizing the performance and efficiency

of your dispersion mixer. With their wide range of products and expertise in the field, Microquick Engineers is committed to helping businesses achieve maximum productivity and profitability.

Understanding Hydraulic Dispersion Kneaders

Hydraulic Dispersion Kneaders are an essential part of the manufacturing process in various industries. These machines play a crucial role in achieving the desired consistency and quality of products.

The main purpose of Hydraulic Dispersion Kneaders is to mix and compound different ingredients to create a homogeneous mixture. A Hydraulic Dispersion Kneader machine consists of several key components that work together to ensure efficient and effective mixing.

The mixing chamber is where the ingredients are combined and processed. It is designed to withstand high pressure and temperature to ensure thorough dispersion. The rotors inside the mixing chamber rotate in opposite directions, creating a shearing and kneading action that helps break down the ingredients and distribute them evenly.

The functions of Hydraulic Dispersion Kneaders include:

- Dispersion: Thorough mixing of ingredients to achieve a uniform blend.

- Distribution: Ensuring all components are evenly spread throughout the mixture.

- Compounding: Combining and processing multiple ingredients to create a final product with desired properties.

These functions are crucial in industries where consistent and high-quality products are required.

Benefits of Hydraulic Dispersion Kneaders

Hydraulic Dispersion Kneaders offer several advantages that enhance efficiency and effectiveness in the manufacturing process.

One significant advantage is the improvement in product quality and consistency. The thorough mixing and dispersion achieved by these kneaders result in a homogeneous mixture, reducing the risk of uneven distribution of ingredients. This leads to products with consistent quality and properties.

Another benefit of Hydraulic Dispersion Kneaders is the reduction in batch preparation time , which ultimately increases productivity. The efficient mixing action and advanced design of these machines allow for faster processing, reducing the time required for each batch. This not only improves productivity but also enables manufacturers to meet tight deadlines and customer demands.

The wear resistance properties of the mixing chamber and rotors in Hydraulic Dispersion Kneaders ensure durability and longevity. The materials used in their construction are designed to withstand the harsh conditions of the manufacturing process, reducing the need for frequent repairs or replacements. This results in cost savings for manufacturers in the long run.

Additionally, Hydraulic Dispersion Kneaders are equipped with energy-saving features, making them more environmentally friendly and cost-effective. These kneaders consume less energy compared to traditional mixing methods , reducing the overall energy consumption of the manufacturing process. This not only helps save on energy costs but also contributes to sustainable manufacturing practices.

Conclusion

Hydraulic Dispersion Kneaders play a vital role in the manufacturing process by ensuring efficient and effective mixing of ingredients. They offer various benefits, including:

- Improved product quality and consistency

- Reduced batch preparation time

- Durability and longevity

- Energy savings

These kneaders have applications in industries such as automotive, industrial manufacturing, consumer products, healthcare, and the electrical industry. With their advanced features and customization options, Hydraulic Dispersion Kneaders are a valuable asset for manufacturers looking to enhance their production processes.

Hydraulic Dispersion Kneaders: Revolutionizing the Rubber Manufacturing Industry

Hydraulic Dispersion Kneaders from Microquick Engineers are a game-changer in the rubber manufacturing industry. These kneaders offer industry-leading performance and excellent compounding results, ensuring consistent quality compounding and efficient batch preparation times of 7-12 minutes.

Superior Dispersion and Homogenization

The automated continuous hydraulic ram pressure on ingredients allows for excellent dispersion and homogenization, resulting in high-quality products.

Operational Convenience

One of the standout features of Microquick Engineers’ Hydraulic Dispersion Kneaders is their operational convenience. These kneaders are designed to produce hard batches with ease, making them suitable for various industries such as automotive, industrial, consumer products, healthcare, electrical, and other rubber industries.

Durability and Longevity

Additionally, the wear-resistant properties of the mixing chamber and rotors ensure durability and longevity.

About Microquick Engineers

Microquick Engineers, with over 25 years of experience in the industry and a high customer satisfaction rate, is a leading manufacturer and exporter of Hydraulic Dispersion Kneaders. To learn more about their products and explore their video library showcasing the kneaders in action, visit their website .

Optimize Your Dispersion Mixer

Find more informative articles and tips on optimizing the performance and efficiency of your dispersion mixer on Microquick Engineers’ blog post titled “10 Tips for Optimizing Performance and Efficiency of Your Dispersion Mixer” .

Enhance Productivity and Quality

Investing in Microquick Engineers’ Hydraulic Dispersion Kneaders will not only enhance your productivity but also improve the overall quality of your rubber products. Don’t miss out on the opportunity to revolutionize your manufacturing process. Take the first step towards maximizing your production efficiency by visiting Microquick Engineers’ website today.