Hydraulic dispersion kneaders play a crucial role in the automotive industry by ensuring consistent quality compounding of rubber parts. Compounding, the process of mixing various ingredients to create rubber compounds, is essential for producing automotive rubber parts with the desired properties of strength, durability, and flexibility.

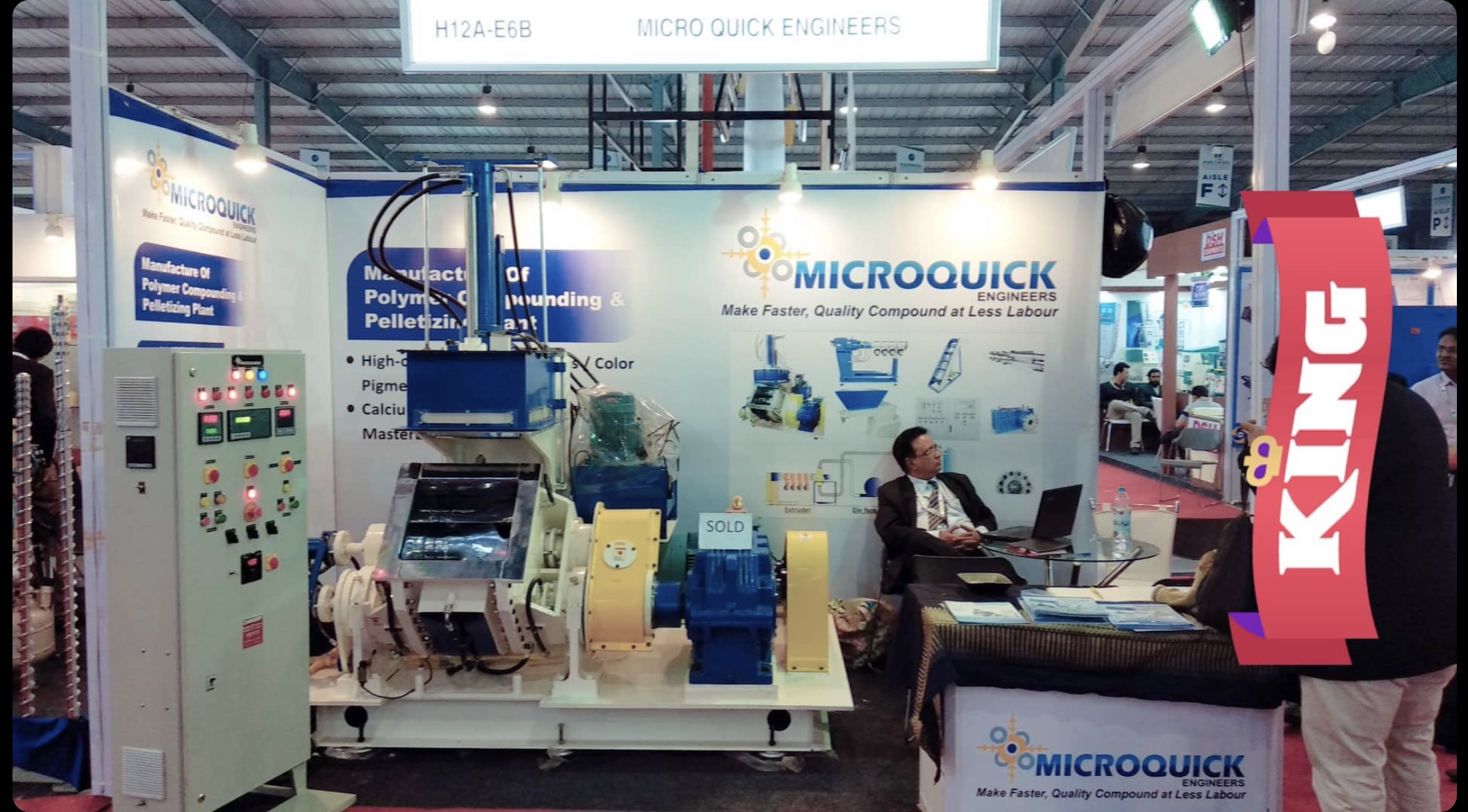

Microquick Engineers: A Trusted Manufacturer of Hydraulic Dispersion Kneaders

Microquick Engineers, a leading manufacturer and exporter of hydraulic dispersion kneaders, understands the importance of compounding in the automotive industry. Their hydraulic dispersion kneaders offer excellent performance, combining automated continuous hydraulic ram pressure on ingredients with batch preparation times ranging from 7-12 minutes. These kneaders provide excellent dispersion of ingredients and consistent quality compounding, making them ideal for producing hard batches and meeting the specific requirements of the automotive industry.

Features and Benefits of Microquick Engineers’ Hydraulic Dispersion Kneaders

-

Excellent dispersion of ingredients

-

Consistent quality compounding

-

Mixing chamber and rotors with wear resistance properties for durability and long-lasting performance

-

Innovative shaft seals with lubrication passage to prevent ingredient leakage

-

Low energy consumption

With over 25 years of experience, Microquick Engineers has established itself as a trusted provider of hydraulic dispersion kneaders in the automotive industry. Their commitment to customer satisfaction and continuous improvement is evident in the features and benefits of their kneaders. These kneaders contribute to the success of the automotive industry by ensuring consistent quality compounding of rubber parts.

Key Features and Benefits of Hydraulic Dispersion Kneaders

Hydraulic dispersion kneaders are an essential tool in the field of compounding, providing excellent ingredient dispersion and consistent quality. These kneaders are designed to automate

the continuous hydraulic ram

pressure on ingredients, resulting in superior compounding performance. Let’s delve deeper into the key features and benefits of

hydraulic dispersion kneaders

.

Definition and Key Features

Hydraulic dispersion kneaders are advanced machines used in the rubber industry for compounding various ingredients. They are equipped with automated continuous

hydraulic ram pressure

, which ensures efficient and uniform mixing. This feature allows for excellent dispersion of ingredients, leading to consistent quality in the final product. Additionally, hydraulic dispersion kneaders have wear-resistant

mixing chambers and rotors

, ensuring durability and extended usage.

Automated Continuous Hydraulic Ram Pressure

The automated continuous hydraulic ram pressure on ingredients is a standout feature of hydraulic dispersion kneaders. This process ensures that the ingredients are consistently and uniformly mixed, resulting in excellent compounding performance. The hydraulic ram applies pressure to the ingredients, forcing them to mix thoroughly. This automated process eliminates the need for manual intervention, making the compounding process more efficient and reducing the risk of human error. The consistent mixing achieved through this automated pressure leads

to superior quality compounds

.

Quick Batch Preparation Times

Batch preparation times play a crucial role in production efficiency. Hydraulic dispersion kneaders offer

batch preparation times

ranging from 7-12 minutes. This quick turnaround time allows for increased productivity and reduces production bottlenecks. With shorter batch preparation times, manufacturers can meet production deadlines and fulfill customer orders more efficiently. This feature significantly impacts the overall production efficiency and helps businesses stay competitive in the market.

Uniform Ingredient Dispersion

The benefits of hydraulic dispersion kneaders extend beyond production efficiency. These machines excel in ingredient dispersion, ensuring that all components are uniformly mixed. This uniform mixing results

in consistent quality compounding

, eliminating variations in the final product. Consistency is key in industries such as automotive, consumer products, healthcare, and electrical, where uniformity and quality are essential. Hydraulic dispersion kneaders provide the reliability and precision needed for these industries to achieve their desired outcomes.

Hydraulic dispersion kneaders offer a range of features and benefits that make them indispensable in the compounding industry. From automated continuous hydraulic ram pressure to quick batch preparation times, these machines ensure excellent ingredient dispersion and consistent quality compounding. Their wear-resistant properties

and innovative shaft seals

further enhance their durability and reliability. With these advanced features, hydraulic dispersion kneaders provide manufacturers with the tools they need to achieve superior compounding performance and stay ahead in the market.

Hydraulic Dispersion Kneaders in Automotive Rubber Parts Manufacturing

Hydraulic dispersion kneaders play a crucial role in the automotive industry, particularly in the manufacturing of rubber parts. These innovative machines offer several applications that contribute

to achieving precise part

dimensions and strength, making them an indispensable tool in the production process. Let’s take a closer look at how

hydraulic dispersion kneaders

are used in automotive rubber parts manufacturing and the advantages they bring to the table.

Applications of Hydraulic Dispersion Kneaders

- Mixing and compounding of rubber compounds

- Extrusion for creating rubber profiles

- Calendering for producing rubber sheets

- Molding of automotive rubber parts

Mixing and Compounding of Rubber Compounds

One of the primary

applications of hydraulic dispersion

kneaders in the automotive industry

is in the mixing and compounding of rubber compounds. These machines excel at uniformly dispersing and blending various ingredients, such as rubber polymers, fillers, plasticizers, and additives, to create high-quality rubber compounds. The precise control over the mixing process ensures that the resulting compound has consistent properties, such as hardness, elasticity, and durability, which are crucial for automotive rubber parts.

Extrusion for Creating Rubber Profiles

In extrusion, the kneader helps create rubber profiles with complex shapes, such as seals, gaskets, and weatherstrips, by forcing the rubber compound through a die. The precise control over the mixing and extrusion processes ensures that the resulting profiles have accurate dimensions and excellent surface finish.

Calendering for Producing Rubber Sheets

In calendering, hydraulic dispersion kneaders are utilized to produce rubber sheets of various thicknesses. These sheets can be further processed into components like belts, hoses, and diaphragms. The kneader’s ability to achieve uniform dispersion and excellent mixing ensures that the resulting sheets have consistent thickness and mechanical properties, meeting the strict standards of the automotive industry.

Molding of Automotive Rubber Parts

Furthermore, hydraulic dispersion kneaders are essential in the molding

of automotive rubber parts

. By precisely controlling the mixing and compounding process, these machines produce rubber compounds with the desired properties, such as flowability and curing characteristics, for injection or compression molding. The resulting molded parts, such as bushings, mounts, and seals, exhibit excellent dimensional accuracy and mechanical strength, meeting the stringent requirements of the automotive industry.

Advantages of Hydraulic Dispersion Kneaders

- Excellent dispersion of ingredients, ensuring consistent quality and performance of the final parts

- Precise control over the mixing process, enabling manufacturers to achieve desired part dimensions and mechanical properties, reducing waste and improving overall efficiency

- Robust construction and durability, making them a reliable investment for automotive manufacturers

Hydraulic Dispersion Kneaders: Revolutionizing the Automotive Industry

Hydraulic dispersion kneaders have revolutionized the automotive industry by offering numerous benefits that improve efficiency and reduce production waste. These machines are designed to provide excellent compounding performance, resulting in consistent quality and enhanced productivity.

Improved Efficiency

One of the key

advantages of hydraulic dispersion

kneaders for the automotive industry

is improved efficiency. These machines utilize automated continuous hydraulic ram pressure on ingredients, ensuring thorough mixing and dispersion. As a result, batch preparation times range from 7-12 minutes, significantly reducing production time and increasing overall efficiency. With faster batch preparation, manufacturers can meet tight deadlines and increase their output without compromising on quality.

Reduced Energy Consumption

Another significant impact of hydraulic

dispersion kneaders in the automotive

industry is their contribution to energy consumption. These machines are engineered

to have low energy consumption

, making them environmentally friendly and cost-effective. As the automotive industry strives to reduce its carbon footprint and improve sustainability, the use of energy-efficient equipment like hydraulic dispersion kneaders aligns with these goals. By minimizing energy consumption, manufacturers can lower their operational costs and contribute to a greener future.

Operational Convenience and Durability

Operational convenience and durability are crucial factors in any manufacturing process, especially in the automotive industry. Hydraulic dispersion kneaders are designed to withstand the demanding production requirements of the automotive sector, particularly for producing hard batches. The mixing chamber and rotors of these machines are built with wear resistance properties, ensuring durability and longevity. This durability not only reduces maintenance costs but also minimizes production downtime, allowing manufacturers to optimize their production processes.

Furthermore, the operational convenience of hydraulic dispersion kneaders makes them an ideal choice for automotive manufacturers. These machines offer ease of use,

with innovative shaft seals

that prevent ingredient leakage and ensure a clean working environment. The lubrication passage in the shaft seals ensures smooth operation and enhances the lifespan of the machine. With their user-friendly design, hydraulic dispersion kneaders provide automotive manufacturers with a hassle-free production experience.

Hydraulic dispersion kneaders offer significant benefits to the automotive industry. Their improved efficiency,

reduced energy consumption

, operational convenience, and durability make them a valuable asset for automotive manufacturers. By investing in these machines, manufacturers can enhance their production processes, reduce waste, and meet the demands of the ever-evolving automotive market. With their advanced features and reliable performance, hydraulic dispersion kneaders are a game-changer in the automotive industry.

Microquick Engineers: A Trusted Manufacturer and Exporter

Microquick Engineers is a leading manufacturer and exporter of hydraulic dispersion kneaders , offering innovative solutions for consistent quality compounding . With over 25 years of experience in the industry, they have established themselves as a trusted name in the market.

Their expertise lies in manufacturing hydraulic dispersion kneaders that deliver excellent compounding performance and operational convenience .

- Automated continuous hydraulic ram pressure on ingredients ensures consistent quality compounding by providing excellent dispersion of ingredients.

- Batch preparation time ranging from 7-12 minutes results in efficient production .

- Mixing chamber and rotors have wear resistance properties , ensuring long-lasting usage.

- Innovative shaft seals with lubrication passage prevent ingredient leakage and ensure smooth operation.

These hydraulic dispersion kneaders are suitable for various industries, including:

- Automotive

- Industrial

- Consumer products

- Healthcare

- Electrical

- Rubber industries

Microquick Engineers’ commitment to customer satisfaction is evident in their high customer satisfaction rate. Their website features positive testimonials from satisfied customers, highlighting their dedication to delivering high-quality products and exceptional service.

When choosing Microquick Engineers as your hydraulic dispersion kneader supplier, you can expect reliable and efficient solutions that meet your specific industry requirements . Their years of experience and industry reputation make them a trusted partner for manufacturers worldwide.

Choose Microquick Engineers for your hydraulic dispersion kneader needs and experience the benefits of their trusted solutions.

The Benefits of Hydraulic Dispersion Kneaders in the Automotive Industry

Hydraulic dispersion kneaders play a crucial role in the automotive industry, offering excellent compounding performance and consistent quality compounding . These kneaders provide efficient production with batch preparation times ranging from 7-12 minutes, making them ideal for producing hard batches.

One of the standout features of hydraulic dispersion kneaders is the wear resistance of the mixing chamber and rotors, ensuring durability and longevity. The innovative shaft seals with lubrication passage prevent ingredient leakage, further enhancing their performance. Additionally, these kneaders have low energy consumption, making them a sustainable choice for various industries, including automotive, industrial, consumer products, healthcare, electrical, and other rubber industries.

Microquick Engineers: A Trusted Manufacturer of Hydraulic Dispersion Kneaders

Microquick Engineers, a leading manufacturer and exporter of Hydraulic Dispersion Kneaders, has over 25 years of experience in the industry and a high customer satisfaction rate. Their kneaders are known for their quality and performance.

Why Choose Microquick Engineers’ Hydraulic Dispersion Kneaders?

- Efficient production with batch preparation times ranging from 7-12 minutes

- Wear resistance of the mixing chamber and rotors for durability and longevity

- Innovative shaft seals with lubrication passage to prevent ingredient leakage

- Low energy consumption for sustainability

- Trusted choice for various industries, including automotive, industrial, consumer products, healthcare, electrical, and other rubber industries

Explore Microquick Engineers’ Solutions

To learn more about the benefits of hydraulic dispersion kneaders and explore Microquick Engineers’ solutions, I encourage you to visit their website at microquick.us . On their website, you’ll find a video library showcasing their products and positive testimonials from satisfied customers. You can also schedule a Zoom call with the Microquick Engineers team to discuss your specific requirements and how their hydraulic dispersion kneaders can enhance your production processes.

In Conclusion

Hydraulic dispersion kneaders are essential equipment for achieving consistent quality compounding in the automotive industry. Microquick Engineers’ expertise and dedication to manufacturing high-quality kneaders make them a trusted choice for companies in various industries. Don’t miss out on the opportunity to enhance your production processes with Microquick Engineers’ hydraulic dispersion kneaders. Visit their website today and schedule a Zoom call to explore their solutions further.