Introduction

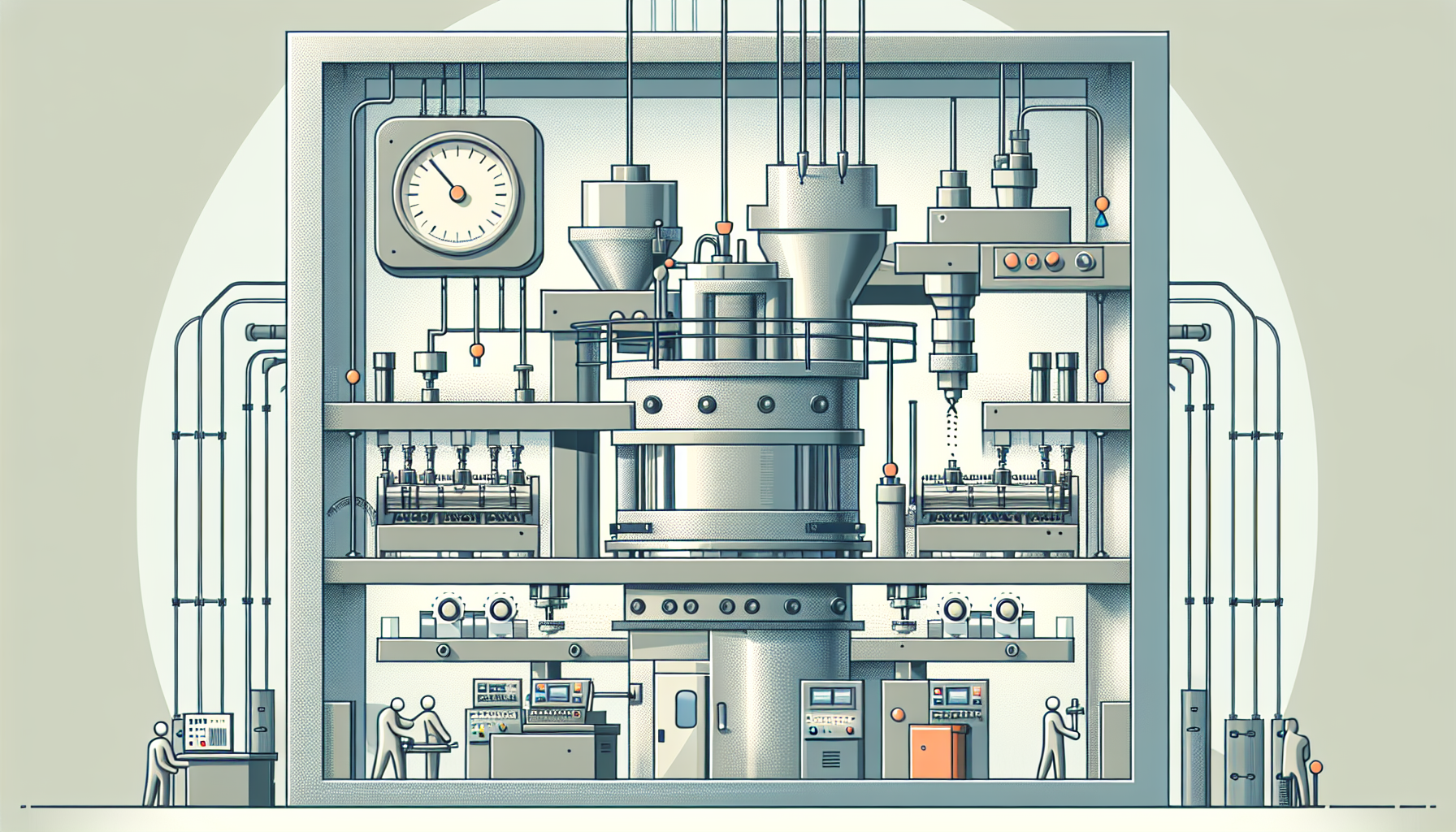

Kneader machines play a crucial role in manufacturing industries, streamlining the mixing and compounding processes. Efficiency in manufacturing is vital for improving production rates, reducing costs, and ensuring consistent product quality. Microquick Engineers’ hydraulic dispersion kneaders significantly enhance efficiency by automating pressure application, offering superior dispersion, and providing consistent quality compounding.

Technical Features of Kneader Machines Contributing to Improved Efficiency

Kneader machines, particularly hydraulic dispersion kneaders, offer several technical features that contribute to improved efficiency in manufacturing industries. These features enhance the mixing and compounding processes, resulting in better dispersion, consistency, and overall product quality.

Positive Pressure Exertion and Accurate Hydraulic Ram Control

Kneader machines exert positive pressure on the batch, ensuring better dispersion of ingredients and batch-to-batch consistency. The accurate control of the hydraulic ram facilitates precise pressure application during the compounding process.

Automation of Constant Pressure on Ingredients

These machines automate the application of constant pressure on ingredients during compounding, resulting in consistent quality batches. This feature minimizes human intervention and reduces the chances of errors in the mixing process.

Elimination of Air Compressors and Uncontrolled Ram Movement

Kneader machines do not require an air compressor, unlike pneumatic cylinders, which often have uncontrolled ram movement. This design choice leads to a more stable and efficient mixing process.

Wider Rotor Tip Width and Stubby Shape

The wider rotor tip width and stubby shape of kneader machines facilitate a large smearing action on ingredients, enhancing the dispersion effect and resulting in quality kneading of ingredients.

Carbide-Coated Rotor Tips for Wear Resistance

Carbide coating on the rotor tips provides wear resistance and maintains clearance for long-lasting smear performance. This feature ensures that the kneader machines maintain their efficiency over time.

Effective Cooling Inside the Rotor and Surrounding Jacket

Kneader machines incorporate effective cooling mechanisms inside the rotor and surrounding jacket. This design enables the compound to be mixed at significantly lower temperatures, reducing the risk of overheating and potential damage to the ingredients.

Anti-Wear Properties and Minimal Clearance in Mixing Chamber

Finally, the mixing chamber of kneader machines boasts anti-wear properties, minimal clearance between rotor tips and the surrounding wall, and a mirror-polished, hard chrome-coated surface for easy ejection of the compound. These features contribute to the overall efficiency and longevity of the machines.

Applications of Kneader Machines in Various Industries

Kneader machines are versatile, and their applications span across a wide range of industries. The improved efficiency, precise control, and consistent quality offered by these machines make them a valuable addition to various manufacturing processes. Here, we will discuss some of the key industries where kneader machines play an essential role.

Automotive Industry

In the automotive industry, kneader machines are used to produce rubber compounds and other materials essential for manufacturing tires, gaskets, hoses, and seals. Their precise mixing capabilities ensure the consistent quality required in this highly regulated industry.

Industrial Applications

From chemical production to the processing of plastics and polymers, kneader machines are widely used in various industrial applications. Their ability to handle different types of materials and efficiently mix them ensures a high-quality end product.

Consumer Products

Kneader machines are also employed in the manufacturing of consumer products, such as adhesives, cosmetics, and household items. The precise mixing and compounding offered by these machines contribute to the consistent quality and performance of the final products.

Healthcare Industry

The healthcare industry relies on kneader machines for the production of pharmaceuticals, medical devices, and other healthcare products. The machines’ ability to maintain consistent quality and meet strict regulatory standards is crucial for ensuring the safety and efficacy of healthcare products.

Electrical Industry

Lastly, kneader machines are used in the electrical industry for manufacturing insulating materials, cables, and other electrical components. The machines’ efficient mixing and compounding capabilities contribute to the production of high-quality, reliable electrical products.

Benefits of Microquick Engineers’ Hydraulic Dispersion Kneaders

Microquick Engineers is a leading manufacturer of hydraulic dispersion kneaders, boasting over 25 years of experience in the industry. Their machines provide exceptional quality compounding and faster production rates, making them a valuable asset to manufacturing industries. Let’s explore some of the key benefits of Microquick Engineers’ hydraulic dispersion kneaders.

Automated and Consistent Batch Preparation

One of the most significant advantages of Microquick Engineers’ kneader machines is their ability to automate and maintain consistent batch preparation. With just 7-12 minutes required for batch preparation time, these machines offer a faster, more efficient production process.

Convenient Production of Hard Batches and Wear Resistance

Microquick Engineers’ kneader machines are designed to conveniently produce hard batches while offering wear resistance in the mixing chamber and rotors. This ensures the machine’s durability and longevity, allowing it to provide reliable performance over time.

Innovative Shaft Seals with Lubrication Passage

Their kneader machines are equipped with innovative shaft seals and a lubrication passage to prevent ingredient leaks and ensure low energy consumption. This design feature contributes to the machine’s efficiency and overall effectiveness in the manufacturing process.

Operator-Friendly Design and Compact Size

Finally, the operator-friendly design and compact size of Microquick Engineers’ kneader machines make them easy to use and integrate into existing manufacturing setups. Their user-focused design enables operators to maximize the machine’s potential and achieve optimal results.

Choosing Microquick Engineers for Hydraulic Dispersion Kneaders

When it comes to selecting a manufacturer for hydraulic dispersion kneaders, Microquick Engineers stands out with their expertise and experience in manufacturing these machines. With over 25 years in the industry, Microquick Engineers has built a reputation for providing high-quality kneader machines that offer value for investment and exceptional performance.

Microquick Engineers not only provides top-of-the-line kneader machines but also offers installation services and support to ensure seamless integration into your manufacturing process. By choosing Microquick Engineers, you can trust that you are investing in reliable and efficient kneader machines backed by an industry-leading company dedicated to customer satisfaction.

Unlock Manufacturing Potential

As we have explored, kneader machines, particularly hydraulic dispersion kneaders, significantly improve efficiency in manufacturing industries. Investing in high-quality kneader machines, such as those offered by Microquick Engineers, ensures consistent quality, faster production, and long-lasting performance. We encourage you to visit Microquick Engineers’ website and download their brochure to learn more about their innovative products and how they can elevate your manufacturing processes.