Rubber compounding is a critical process in various industries, including automotive, industrial, consumer products, healthcare, and electrical sectors. Achieving consistent quality and efficient compounding is essential for manufacturers to meet the demands of these industries. That’s where advanced hydraulic dispersion kneaders come into play.

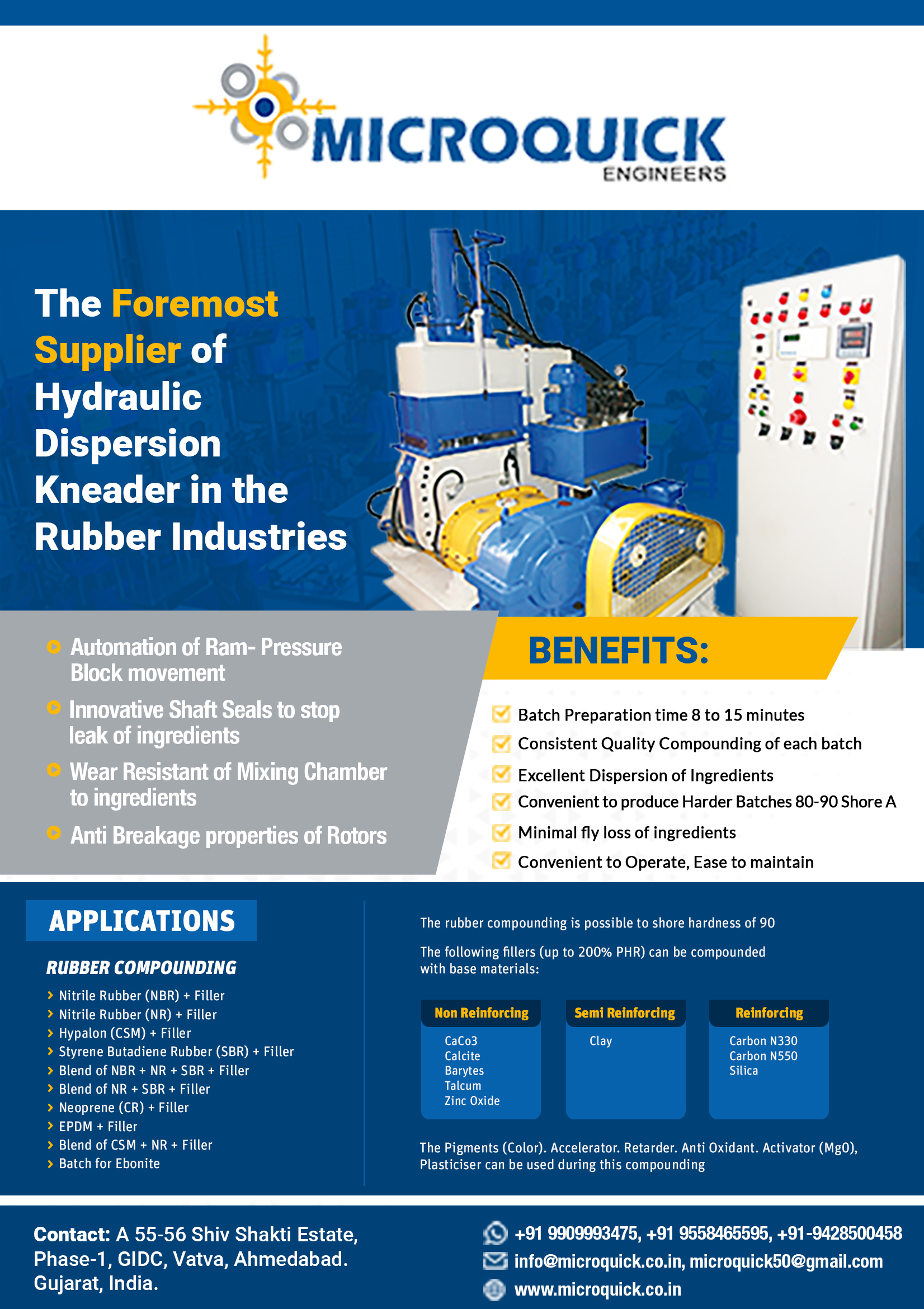

Microquick Engineers , a trusted manufacturer and exporter, offers innovative hydraulic dispersion kneaders that revolutionize the rubber compounding process. These kneaders provide excellent ingredient dispersion and consistent quality compounding, ensuring superior batch preparation times of 7-12 minutes.

Key Features of Microquick’s Hydraulic Dispersion Kneaders

-

Durability and wear resistance: The mixing chamber and rotors are designed to withstand the demanding conditions of rubber compounding, resulting in long-lasting performance.

-

Leakage prevention: Innovative shaft seals with lubrication passages prevent ingredient leakage, ensuring a clean and efficient process.

-

Low energy consumption: These advanced kneaders offer low energy consumption, making them environmentally friendly and energy efficient.

-

Versatility: Microquick’s hydraulic dispersion kneaders cater to the specific needs of different industries, including the automotive, industrial, consumer products, healthcare, and electrical sectors.

With over 25 years of experience in the industry, Microquick Engineers have established themselves as a reliable choice for manufacturers seeking to enhance their rubber compounding process . Their hydraulic dispersion kneaders provide industry-leading performance and are backed by a high customer satisfaction rate.

In the following sections, we will delve deeper into the working principle of hydraulic dispersion kneaders , explore their advantages in the rubber compounding process, and provide real-world examples and case studies. Stay tuned to discover how these advanced kneaders can elevate your rubber compounding process.

Understanding Rubber Compounding

Understanding rubber compounding is crucial

for achieving consistent quality

and performance in rubber products. Rubber compounding involves the mixing of various raw materials to create a rubber compound with desired properties. It is a complex process that requires precision and expertise.

One of the main challenges faced during rubber compounding is achieving uniform dispersion of ingredients. Uniform dispersion is essential to ensure that all components are evenly distributed throughout the rubber compound, resulting in consistent quality and performance. Traditional mixing methods often struggle to achieve this level of dispersion, leading to batch variations and compromised product quality.

Advanced Hydraulic Dispersion Kneaders

This is where advanced hydraulic dispersion kneaders from Microquick Engineers come into play. These innovative machines offer industry-leading performance with automated continuous hydraulic ram pressure on ingredients. The result is excellent dispersion of ingredients and consistent quality compounding.

Benefits of Hydraulic Dispersion Kneaders

- Significantly reduce batch preparation times (7-12 minutes)

- Convenient for producing hard batches

- Engineered with wear resistance properties for durability

- Innovative shaft seals with lubrication passages to prevent ingredient leakage

- Energy efficient with low energy consumption

- Find applications in various industries including automotive, industrial, consumer products, healthcare, electrical, and other rubber industries

About Microquick Engineers

Microquick Engineers is a trusted manufacturer and exporter

with over 25 years of experience

. They offer a range

of hydraulic dispersion kneaders

that cater to the diverse needs of the rubber industry. Their commitment to delivering high-quality products and customer satisfaction is evident through their positive testimonials and industry experience.

Learn More

To learn more about the advanced hydraulic dispersion kneaders from Microquick Engineers, you can visit their website and explore their video library showcasing their products in action. The website also provides valuable resources, such as a blog post

on optimizing the performance and efficiency

of dispersion mixers. For further inquiries, you can download their brochure or contact Microquick Engineers directly.

By addressing the challenges faced during the compounding process, advanced hydraulic dispersion kneaders offer a solution that enhances efficiency, reduces

batch preparation times

, ensures excellent ingredient dispersion, and promotes sustainability. Microquick Engineers’ expertise in manufacturing these kneaders makes them a reliable partner for the rubber industry.

Advantages of Hydraulic Dispersion Kneaders in Rubber Compounding

One of the main

advantages of using hydraulic

dispersion kneaders in rubber

compounding is the improved batch preparation times. Microquick Engineers, a leading manufacturer and exporter of hydraulic dispersion kneaders, offers industry-leading performance with automated continuous hydraulic ram pressure on ingredients. This results in batch preparation times of 7-12 minutes, making the compounding process highly efficient.

Streamlined and Accelerated Process

Traditional rubber compounding processes can be time-consuming and labor-intensive, requiring manual mixing and longer

batch preparation times

. However,

with hydraulic dispersion kneaders

, the process is streamlined and accelerated, allowing for faster production and increased productivity.

Benefits of Reduced Batch Preparation Times

The reduced batch preparation times offered by hydraulic dispersion kneaders have several benefits:

- Efficient meeting of tight production schedules and customer demands

- Less downtime and increased overall production capacity

- Particularly advantageous in industries with high production volumes

Excellent Ingredient Dispersion and Consistent Quality Compounding

In addition to improved batch preparation times, hydraulic dispersion kneaders also offer excellent ingredient dispersion

and consistent quality compounding

. Microquick Engineers’ kneaders are designed to provide optimal mixing and dispersion of ingredients, ensuring uniformity throughout the compound. This results in consistent quality compounds with improved physical properties and performance.

Durability and Wear Resistance

Hydraulic dispersion kneaders, such as those from Microquick Engineers, are known for their durability and wear resistance. The mixing chamber and rotors of these kneaders are specifically designed to withstand the demanding conditions of rubber compounding. This ensures long-lasting performance and minimizes downtime and maintenance costs.

Innovative Shaft Seals

To enhance the performance and reliability of their kneaders, Microquick Engineers have incorporated

innovative shaft seals

with lubrication passages. These seals prevent ingredient leakage and ensure a clean and efficient mixing process. By minimizing ingredient loss and contamination, manufacturers can achieve higher yields and reduce waste, ultimately leading to cost savings.

Low Energy Consumption

Another significant advantage of hydraulic dispersion kneaders

is their low energy consumption

. Compared

to traditional mixing methods

, hydraulic dispersion kneaders operate with greater energy efficiency. This not only helps reduce operational costs but also contributes to environmental sustainability.

Hydraulic dispersion kneaders offer several advantages in rubber compounding. Improved batch preparation times, excellent ingredient dispersion, durability, innovative shaft seals, and low energy consumption are key features that make these kneaders highly desirable for manufacturers in various industries. Microquick Engineers,

with over 25 years of experience

in the industry, is a trusted manufacturer and exporter of hydraulic dispersion kneaders, providing reliable solutions

that enhance rubber compound

quality and production efficiency.

To learn more about Microquick Engineers’ hydraulic dispersion kneaders and see them in action, you can visit their website and explore their video library. They also offer a blog post with valuable

tips for optimizing the performance

and efficiency of your dispersion mixer

. If you’re interested in their products or have any inquiries, you can download their brochure or contact Microquick Engineers directly through their website.

Applications and Benefits of Hydraulic Dispersion Kneaders

In the previous sections, we discussed the working principle

and advantages of hydraulic dispersion

kneaders in the rubber compounding

process. Now, let’s explore the various applications and benefits of these innovative machines in different industries.

Automotive Industry

The automotive industry heavily relies on rubber compounds for various applications such as tires, seals, gaskets, and hoses. Hydraulic dispersion kneaders play a crucial role in improving

the quality and efficiency of rubber

compounding in this sector. With their excellent ingredient dispersion capabilities, these kneaders ensure that the rubber compounds used in the automotive industry have consistent and uniform properties. This leads to enhanced performance, durability, and safety of automotive components.

Industrial and Consumer Products Sector

In the industrial and consumer products sector, hydraulic dispersion kneaders find applications in the production of rubber products like conveyor belts, industrial hoses, and seals. These kneaders offer several benefits in this sector:

- Reduced batch preparation times of 7-12 minutes, enabling manufacturers to optimize production processes and meet the growing demand for rubber products.

- Excellent dispersion of ingredients, resulting in superior quality and performance of the final products.

Healthcare and Electrical Sectors

The healthcare and electrical sectors require specialized rubber compounds for applications such as medical devices, electrical insulators, and cables. Hydraulic dispersion kneaders are well-suited for these sectors due to their ability to produce rubber compounds with precise ingredient dispersion and consistent quality. This is crucial for ensuring the safety and reliability of healthcare and electrical products.

Real-World Examples and Case Studies

To further illustrate the applications

and benefits of hydraulic dispersion

kneaders, let’s take a look at some real-world examples and case studies:

- High-performance tires for racing cars: The precise ingredient dispersion achieved by hydraulic dispersion kneaders enhances the traction, handling, and overall performance of these tires on the race track.

- Medical-grade rubber components for critical healthcare applications: Hydraulic dispersion kneaders ensure that the rubber compounds used in these components have excellent biocompatibility, flexibility, and durability. This is essential for maintaining the highest standards of patient safety and product reliability.

To explore more about the applications and benefits of hydraulic dispersion kneaders, you can visit our website https://microquick.us/ . We have a video library showcasing our products and positive testimonials from satisfied customers. Additionally, you can download our brochure for more information and reach out to us for any inquiries. At Microquick Engineers,

we have over 25 years of experience

in the industry and a high

customer satisfaction rate

. We are committed to providing innovative solutions that enhance the quality and efficiency of rubber compounding.

Microquick Engineers: Trusted Manufacturer and Exporter

Microquick Engineers has established itself as a trusted manufacturer and exporter in the industry. With over 25 years of experience and expertise, they have become a reliable choice for manufacturers worldwide. Let’s delve into the reasons behind their reputation and the key

features of their hydraulic dispersion

kneaders.

Experience and Expertise

Microquick Engineers’ extensive experience in the industry sets them apart from their competitors. With over two decades of knowledge and expertise, they have gained a deep understanding of the challenges faced in rubber compounding. This experience has enabled them to develop innovative solutions that enhance the quality and efficiency of the compounding process.

Key Features and Benefits of Microquick’s Hydraulic Dispersion Kneaders

Microquick’s

hydraulic dispersion kneaders

offer a range

of key features and benefits

that make them an excellent choice for manufacturers. Let’s take a look:

-

Automated continuous hydraulic ram pressure:

Ensures consistent and efficient compounding, resulting in high-quality rubber compounds. -

Reduced batch preparation times:

Complete the compounding process in just 7-12 minutes, saving valuable time and increasing productivity. -

Excellent dispersion of ingredients and consistent quality compounding:

Thoroughly mixes all ingredients, resulting in a homogenous compound with superior properties. -

Durability and wear resistance:

Designed with wear-resistant properties to withstand high-intensity mixing, ensuring long-lasting performance and minimal downtime. -

Innovative shaft seals with lubrication passages:

Prevents ingredient leakage and ensures a clean and efficient mixing process. -

Low energy consumption:

Designed with energy efficiency in mind, allowing manufacturers to achieve sustainability goals without compromising performance.

Applications and Industry Experience

Microquick’s hydraulic dispersion kneaders find

applications in various industries

, including:

- Automotive industry

- Industrial and consumer products sector

- Healthcare

- Electrical sectors

The versatility of these kneaders makes them suitable for a wide range of rubber compounding applications.

Microquick Engineers have garnered a reputation

for their exceptional customer service

and satisfaction. Their commitment to providing high-quality products and comprehensive support has earned them a loyal customer base. Their website features positive testimonials from satisfied customers, further showcasing their industry experience and expertise.

Microquick Engineers’ status as a trusted manufacturer and exporter is well-deserved. With their extensive experience, innovative features, and commitment to customer satisfaction, they have positioned themselves as a reliable choice in the industry. Whether it’s reducing

batch preparation times

, ensuring excellent ingredient dispersion, or providing durable and energy-efficient solutions, Microquick’s hydraulic dispersion kneaders offer exceptional performance and value to manufacturers worldwide.

To learn more about Microquick’s hydraulic dispersion kneaders, you can visit their website, which includes a video library showcasing their products and positive testimonials from satisfied customers. Additionally, you can explore their blog for valuable

tips on optimizing the performance

and efficiency of your dispersion mixer

. For further inquiries, you can download their brochure or contact Microquick Engineers directly.

The Future of Rubber Compounding

Rubber compounding has come a long way and continues to evolve with emerging trends, advancements in manufacturing plants and technologies, and the potential of artificial intelligence. These factors are shaping the future of rubber compounding , and it’s important for industry professionals to stay updated and adapt to these changes.

Emerging Trends in Rubber Compounding

The use of innovative hydraulic dispersion kneaders is a key trend revolutionizing the compounding process. These kneaders, offered by Microquick Engineers, enhance rubber compound quality and provide industry-leading performance. They offer the following advantages:

- Excellent Ingredient Dispersion: Hydraulic dispersion kneaders ensure thorough mixing of the rubber compound, resulting in consistent quality compounding. Automated continuous hydraulic ram pressure improves the dispersion process and eliminates the need for manual intervention.

- Reduced Batch Preparation Times: Batch preparation times range from 7 to 12 minutes, significantly improving the efficiency of the compounding process. This allows manufacturers to increase their production capacity and meet market demands.

- Durability and Wear Resistance: The mixing chambers and rotors of Microquick Engineers’ hydraulic dispersion kneaders have wear resistance properties, enabling them to handle hard batches without compromising performance or longevity.

- Innovative Shaft Seals: The kneaders feature innovative shaft seals with lubrication passages, preventing ingredient leakage and ensuring a clean and efficient compounding process. This minimizes waste and improves overall production efficiency.

The Potential of Artificial Intelligence

Artificial intelligence (AI) has the potential to optimize the compounding process for improved quality and efficiency. AI can analyze complex data sets, identify patterns and trends, and optimize the compounding process for more accurate and precise results.

The Environmental Benefits

In addition to improving quality and efficiency, the use of hydraulic dispersion kneaders offers environmental benefits. These kneaders have low energy consumption , making them an eco-friendly choice for rubber compounding.

In conclusion, the future of rubber compounding lies in the adoption of emerging trends, advancements in manufacturing plants and technologies, and the potential of artificial intelligence. By embracing these changes, manufacturers can enhance the quality and efficiency of their compounding process and stay ahead in the competitive market. Microquick Engineers’ hydraulic dispersion kneaders offer industry-leading performance, excellent ingredient dispersion, reduced batch preparation times, and durability. With over 25 years of experience in the industry, Microquick Engineers is a trusted manufacturer and exporter of hydraulic dispersion kneaders. Stay tuned for more updates on the future of rubber compounding and explore the range of kneaders offered by Microquick Engineers.

Enhance Your Rubber Compounding Process with Advanced Hydraulic Dispersion Kneaders

Advanced hydraulic dispersion kneaders from Microquick Engineers offer numerous benefits for enhancing rubber compounding processes. These kneaders are designed with industry-leading performance, featuring automated continuous hydraulic ram pressure on ingredients. With batch preparation times of 7-12 minutes, the compounding process becomes highly efficient.

Benefits of Advanced Hydraulic Dispersion Kneaders

- Excellent Ingredient Dispersion: The kneaders ensure excellent dispersion of ingredients, resulting in consistent quality compounding.

- Durable and Long-lasting: The mixing chamber and rotors are designed with wear-resistant properties, ensuring durability and long-lasting performance.

- Prevention of Ingredient Leakage: Innovative shaft seals with lubrication passages prevent ingredient leakage, enhancing operational convenience.

Industries Served

Microquick Engineers’ hydraulic dispersion kneaders are suitable for various industries , including:

- Automotive

- Industrial

- Consumer Products

- Healthcare

- Electrical

- Rubber Industries

Why Choose Microquick Engineers?

With over 25 years of experience in the industry, Microquick Engineers is a trusted manufacturer and exporter of hydraulic dispersion kneaders. They have established themselves as reliable partners in the rubber compounding process , with a high customer satisfaction rate.

Explore Microquick Engineers’ Solutions

To explore the advanced hydraulic dispersion kneaders from Microquick Engineers, you can visit their website and access their video library showcasing their products. Additionally, you can read their blog post titled “10 Tips for Optimizing Performance and Efficiency of Your Dispersion Mixer” to gain insights into maximizing the performance of your compounding process. For more information and inquiries, you can download their brochure and find contact information on their website.

Enhance your rubber compounding process with the advanced hydraulic dispersion kneaders from Microquick Engineers. Experience improved efficiency, consistent quality, and durability in your compounding process. Explore Microquick Engineers’ Solutions today!