In today’s fast-paced industries, efficiency is key to staying ahead of the competition. One area where efficiency plays a crucial role is in rubber compounding . Efficiently mixing rubber compounds can have a significant impact on the quality and productivity of various industries, including automotive, industrial, consumer products, healthcare, and electrical sectors.

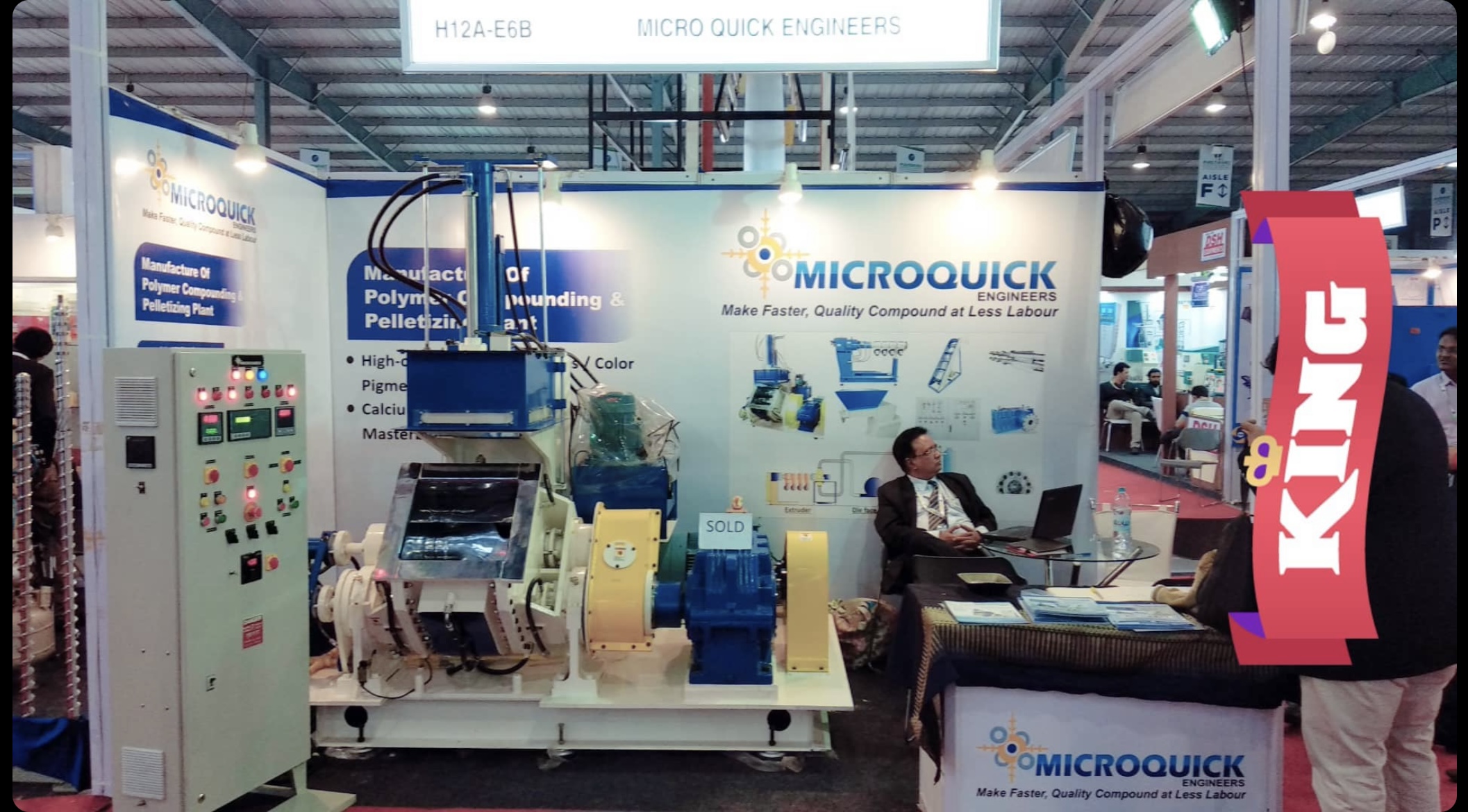

One technology that has revolutionized the rubber compounding process is hydraulic dispersion kneaders . These innovative machines, offered by Microquick Engineers, provide excellent compounding performance and automation, resulting in batch preparation times of just 7-12 minutes. With their automated continuous hydraulic ram pressure on ingredients, these kneaders ensure excellent dispersion and consistent quality compounding.

What Sets Microquick Engineers’ Hydraulic Dispersion Kneaders Apart

-

Wear-resistant design for durability and longevity

-

Energy-efficient with low energy consumption

-

Operator-friendly with user-friendly interfaces and intuitive operational system

-

Exceptional after-sales support and services, including installation, training, maintenance, troubleshooting, and spare parts availability

With over 25 years of experience in the industry, Microquick Engineers is a trusted manufacturer and exporter of hydraulic dispersion kneaders. Their kneaders are customizable to meet specific industry requirements , making them the ideal solution for efficiently mixing rubber compounds.

Discover the Benefits of Microquick Engineers’ Hydraulic Dispersion Kneaders

Explore Microquick Engineers’ solutions to enhance the efficiency of rubber compound mixing.

Working Mechanism of Hydraulic Dispersion Kneaders

Dispersion kneaders play a crucial

role in the rubber compounding

process, ensuring that the ingredients are thoroughly mixed to achieve consistent and high-quality compounds. In this section, we will explore the working mechanism

of hydraulic dispersion kneaders

and highlight their benefits.

Description of the Mixing Process in Hydraulic Dispersion Kneaders

Hydraulic dispersion kneaders, such as the ones offered by Microquick Engineers, are designed to provide excellent compounding performance and efficiency. These kneaders utilize

a hydraulic ram pressure

system to continuously compress and mix the ingredients, resulting

in batch preparation times

as low as 7-12 minutes.

The mixing process in hydraulic dispersion kneaders starts with the introduction of the raw materials into the mixing chamber. The hydraulic ram exerts pressure on the ingredients, forcing them to interact and blend together. The kneading action of the rotors further enhances the dispersion of the ingredients, ensuring that they are evenly distributed throughout the compound.

Benefits of Hydraulic Dispersion Kneaders

- Excellent dispersion of ingredients, leading to uniformity and consistency in the final product.

- Enhanced properties of compounds, such as improved tensile strength, elongation, and abrasion resistance.

- Durable and long-lasting mixing chamber and rotors with wear resistance properties.

- Energy-efficient, contributing to cost savings for manufacturers.

- Automation and continuous hydraulic compression system for consistent results and reduced human error.

- Suitable for a wide range of industries, including automotive, industrial, consumer products, healthcare, electrical, and other rubber industries.

To further optimize

the performance and efficiency of dispersion

kneaders, Microquick Engineers provides useful tips in a blog post titled “10 Tips for Optimizing Performance and Efficiency of Your Dispersion Mixer” on their website. These tips can help manufacturers make the most out of their hydraulic dispersion kneaders and achieve even better results.

Hydraulic dispersion kneaders offer a highly efficient and effective mixing process for rubber compounding. Their ability to achieve excellent dispersion, along with their durability, energy efficiency, and automation features, makes them a valuable investment for manufacturers in various industries. By choosing hydraulic dispersion kneaders from Microquick Engineers, businesses can enhance the quality and efficiency of their rubber compounding process.

The Advantages of Hydraulic Dispersion Kneaders

Hydraulic dispersion kneaders have become an essential tool

in the rubber compounding industry

due to their numerous benefits. In this section, we will explore the advantages of using

hydraulic dispersion kneaders

and how they contribute to improved efficiency, productivity, and overall quality in batch preparation.

Enhanced Efficiency and Productivity

One of the key

benefits of hydraulic dispersion

kneaders is their ability to significantly enhance the efficiency and productivity of batch preparation. Traditional methods of rubber compounding often require extensive manual labor and time-consuming processes. However, hydraulic dispersion kneaders streamline this process by automating the mixing and dispersion of rubber compounds.

By utilizing automated

continuous hydraulic ram

pressure, hydraulic dispersion kneaders

can reduce batch preparation

times to an impressive 7-12 minutes. This not only saves valuable time but also increases productivity, allowing manufacturers to produce larger quantities of rubber compounds in a shorter period. With faster batch preparation times, companies can meet demanding production schedules and deliver products to the market more quickly.

Excellent Dispersion Capabilities

Additionally, hydraulic dispersion kneaders offer excellent dispersion capabilities, resulting in consistent and high-quality compounding. The unique design of these kneaders ensures that all ingredients are thoroughly mixed and dispersed evenly throughout the rubber compound. This homogenous dispersion is crucial for achieving consistent and reliable product quality.

Consistency is particularly important in industries such as automotive, industrial, consumer products, healthcare, and electrical sectors, where the performance and durability of rubber products are critical. Hydraulic dispersion kneaders ensure that the rubber compounds meet the stringent quality standards of these industries, enhancing the overall product performance and customer satisfaction.

Operational Convenience and Versatility

Furthermore, hydraulic dispersion kneaders provide operational convenience and versatility for different rubber compounds. These kneaders can be customized to meet

specific industry requirements

, allowing manufacturers to produce a wide range of rubber compounds with ease. The user-friendly features and intuitive PLC-HMI operational system make it easy for operators to control and monitor the mixing process, ensuring optimal results.

Low Energy Consumption and Cost-Effectiveness

In addition to their efficiency and versatility, hydraulic dispersion kneaders are also known

for their low energy consumption

and cost-effectiveness. These kneaders are designed to minimize energy waste, making them energy-efficient and environmentally friendly. With lower energy consumption, manufacturers can reduce their operating costs and improve their overall cost-effectiveness.

Microquick Engineers, a trusted manufacturer and exporter of hydraulic dispersion kneaders

with over 25 years of experience

, offers a range of kneaders that embody all these advantages. Their kneaders are designed with wear-resistant properties, ensuring durability and longevity. Microquick Engineers also provides exceptional after-sales support, including installation, training, maintenance, troubleshooting, and spare parts availability, further enhancing the customer experience.

Hydraulic dispersion kneaders offer numerous benefits that significantly improve the efficiency, productivity, and quality of batch preparation in rubber compounding. With their automated continuous

hydraulic ram pressure

, excellent dispersion capabilities, operational convenience, versatility, low energy consumption, and cost-effectiveness, hydraulic dispersion kneaders are revolutionizing the rubber compounding industry. Manufacturers can rely on these kneaders to streamline their production processes, meet demanding schedules, and deliver consistent and high-quality rubber compounds to various industries.

Healthcare and Electrical Sectors: Meeting Specific Industry Requirements with Hydraulic Dispersion Kneaders

Hydraulic dispersion kneaders are not only beneficial in the automotive and industrial sectors but also find applications

in the healthcare and electrical industries

. These industries have specific requirements when it comes to rubber compound mixing, and

hydraulic dispersion kneaders

prove to be a reliable solution.

Benefits in the Healthcare Sector

In the healthcare sector,

the quality and consistency of rubber

compounds are of utmost importance. Medical devices and equipment often require rubber components that meet stringent standards for safety and performance. Hydraulic dispersion kneaders ensure

excellent dispersion of ingredients

, resulting in consistent and high-quality rubber compounds. This is crucial for the healthcare industry, as any compromise in quality can have serious consequences for patient safety.

Additionally, hydraulic dispersion kneaders offer operational convenience and versatility, making them suitable for various applications in the healthcare sector. The user-friendly features and intuitive PLC-HMI operational system make it easier for operators to control and monitor the mixing process. This ensures that the rubber compounds meet the specific requirements of medical devices, such as flexibility, durability, and resistance to chemicals and sterilization processes.

Benefits in the Electrical Sector

In the electrical sector, hydraulic dispersion kneaders play a vital role in meeting industry requirements. Rubber compounds are used in the manufacturing of electrical cables, connectors, and insulation materials. These components need to exhibit excellent electrical insulation properties, mechanical strength, and resistance to heat and chemicals. Hydraulic dispersion kneaders ensure the uniform dispersion of conductive and insulating materials, resulting in consistent and high-quality rubber compounds. This is crucial for the electrical industry, as any variation in the composition of rubber compounds can lead to electrical failures or safety hazards.

Furthermore, the wear resistance properties of the mixing chamber

and rotors in hydraulic dispersion

kneaders ensure durability and longevity, even when processing materials with abrasive properties. This is particularly important in the electrical industry, where the equipment needs to withstand repeated use and maintain its performance over time.

Energy Efficiency and Cost-Effectiveness

The low energy consumption of hydraulic dispersion kneaders makes them energy-efficient and cost-effective

for the healthcare and electrical sectors

. This helps in reducing operational costs and environmental impact, aligning with the sustainability goals of many companies in these industries.

Customized Solutions from Microquick Engineers

Microquick Engineers, a leading manufacturer and exporter of hydraulic dispersion kneaders, understands the specific requirements of the healthcare and electrical sectors. With over 25 years of experience in the industry, they offer customized solutions to meet the unique needs of these industries. Their hydraulic dispersion kneaders provide excellent compounding performance and can be tailored to meet the specific demands of the healthcare and electrical sectors.

Hydraulic dispersion kneaders have diverse applications in the healthcare and electrical sectors. They ensure the production of consistent and high-quality rubber compounds that meet the stringent requirements of these industries. With their operational convenience, durability, and energy efficiency, hydraulic dispersion kneaders are a reliable choice for meeting

the specific industry requirements

in the healthcare and electrical sectors.

Microquick Engineers: Your Trusted Solution for Hydraulic Dispersion Kneaders

When it comes

to manufacturing hydraulic dispersion

kneaders, Microquick Engineers is the name you can trust. With over 25 years of experience in the industry, Microquick Engineers has established itself as a leading manufacturer and exporter of high-quality hydraulic dispersion kneaders. Let’s explore why Microquick Engineers stands out from the competition and how their hydraulic dispersion kneaders can benefit your business.

Unique Selling Points of Microquick’s Hydraulic Dispersion Kneaders

- Excellent compounding performance: Microquick’s hydraulic dispersion kneaders are designed to provide efficient and consistent mixing of rubber compounds, ensuring high-quality end products.

- Automated continuous hydraulic ram pressure: Reduces batch preparation times to an impressive 7-12 minutes, improving productivity and efficiency of the compounding process.

- Excellent dispersion of ingredients: Crucial for industries like automotive, industrial, consumer products, healthcare, electrical, and other rubber industries.

- Durability and longevity: Designed with wear-resistant properties in the mixing chamber and rotors to withstand the rigorous demands of the compounding process.

- Energy-efficient: Microquick’s hydraulic dispersion kneaders have low energy consumption, making them cost-effective and environmentally friendly.

Customization Options and Meeting Specific Industry Needs

Microquick Engineers understands that each industry has unique requirements. They offer customization options to meet specific industry needs, including capacity, specialized features, and controls. This ensures that you get a kneader perfectly suited to your industry and application.

Operator-Friendly Features and Intuitive Operational System

Microquick’s

hydraulic dispersion kneaders

are designed with the operators in mind. Equipped with user-friendly features and an intuitive PLC-HMI operational system, these kneaders make operation smooth and hassle-free. This design improves efficiency and reduces the learning curve for new operators.

Exceptional After-Sales Support and Services Provided by Microquick Engineers

Microquick Engineers goes the extra mile to ensure customer satisfaction. They provide exceptional after-sales support and services, including installation, training, maintenance, troubleshooting, and spare parts availability. This level of support gives customers peace of mind, knowing that Microquick Engineers is there to assist them whenever they need it.

Microquick Engineers is a trusted manufacturer and exporter of hydraulic dispersion kneaders, known for delivering high-quality products

and exceptional customer service

. Their unique selling points, customization options, operator-friendly features, and outstanding after-sales support set them apart from the competition. If you’re looking for a reliable and efficient solution

for your rubber compounding needs

, Microquick Engineers should be your go-to choice.

To learn more about Microquick Engineers and their hydraulic dispersion kneaders, visit their website [Link]. You can also find helpful

tips for optimizing the performance

and efficiency of dispersion mixers in their blog post titled “10 Tips for Optimizing Performance and Efficiency of Your Dispersion Mixer” [Link]. For further inquiries or to request a brochure, you can contact Microquick Engineers through their website [Link].

Remember, when it comes to hydraulic dispersion kneaders, trust Microquick Engineers for unparalleled quality and performance.

Tips for Optimizing the Performance and Efficiency of Hydraulic Dispersion Kneaders

Hydraulic dispersion kneaders are a valuable tool in the rubber compounding industry , offering improved efficiency and high-quality results. In this section, we will explore some key tips for optimizing the performance and efficiency of these kneaders, helping you make the most of this technology.

Select the Right Kneader

One important aspect to consider is the selection of the right hydraulic dispersion kneader for your specific needs. Microquick Engineers, a trusted manufacturer and exporter in this field, offers a range of kneaders designed to meet different industry requirements. By choosing a kneader that is tailored to your application, you can ensure optimal performance and efficiency.

Utilize Automated Continuous Hydraulic Ram Pressure

Take advantage of the automated continuous hydraulic ram pressure feature offered by Microquick Engineers’ hydraulic dispersion kneaders. This feature allows for precise control over the mixing process , resulting in faster batch preparation times of 7-12 minutes. By reducing the time required for each batch, you can improve overall productivity and efficiency.

Ensure Excellent Dispersion

The excellent dispersion capabilities of these kneaders play a crucial role in achieving consistent and high-quality compounding. The mixing chamber and rotors of Microquick Engineers’ kneaders are designed with wear-resistant properties, ensuring durability and longevity. This means that you can rely on these kneaders to consistently deliver excellent dispersion, resulting in uniform compound quality.

Minimize Energy Consumption

Energy efficiency is another important consideration when optimizing the performance of hydraulic dispersion kneaders. Microquick Engineers’ kneaders are designed with low energy consumption in mind, making them not only cost-effective but also environmentally friendly. By minimizing energy waste, you can further enhance the efficiency of your compounding process.

Utilize User-Friendly Features

To fully optimize the performance and efficiency of hydraulic dispersion kneaders, it’s essential to make use of the user-friendly features and intuitive PLC-HMI operational system provided by Microquick Engineers. These kneaders are designed to be operator-friendly, making it easy for users to control and monitor the mixing process. By leveraging these features, you can streamline operations and maximize efficiency.

Take Advantage of After-Sales Support

Finally, it’s worth noting that Microquick Engineers provides exceptional after-sales support and services, including installation, training, maintenance, troubleshooting, and spare parts availability. This level of support ensures that you can keep your hydraulic dispersion kneaders operating at their best, minimizing downtime and optimizing performance.

In conclusion, optimizing the performance and efficiency of hydraulic dispersion kneaders involves several key considerations. By selecting the right kneader for your application, utilizing automated features, ensuring excellent dispersion, minimizing energy consumption, leveraging user-friendly features, and taking advantage of after-sales support, you can maximize the benefits of this technology. With Microquick Engineers’ hydraulic dispersion kneaders, you can achieve efficient and high-quality rubber compounding, enhancing your productivity and competitiveness in the industry.

The Importance of Efficient Rubber Compound Mixing with Hydraulic Dispersion Kneaders

Efficiently mixing rubber compounds with hydraulic dispersion kneaders is essential for achieving high-quality and consistent results in the rubber compounding process. Microquick Engineers, a trusted manufacturer and exporter with over 25 years of experience, offers cutting-edge Hydraulic Dispersion Kneaders that deliver exceptional performance.

Key Features of Microquick Engineers’ Hydraulic Dispersion Kneaders

- Automated continuous hydraulic ram pressure on ingredients, resulting in batch preparation times of 7-12 minutes

- Improved efficiency and excellent dispersion of ingredients

- Suitable for a wide range of industries, including automotive, industrial, consumer products, healthcare, electrical, and other rubber industries

- Wear resistance properties for durability and longevity

- Low energy consumption for energy-efficiency and cost-effectiveness

- Customization options available to meet unique industry requirements

- User-friendly features and intuitive PLC-HMI operational system

- Exceptional after-sales support and services

Additional Resources and Contact Information

For more information on optimizing the performance and efficiency of dispersion mixers, you can refer to Microquick Engineers’ blog post titled “10 Tips for Optimizing Performance and Efficiency of Your Dispersion Mixer”. To explore Microquick Engineers’ solutions for efficient rubber compound mixing, visit their website at https://microquick.us/ . You can also download their brochure here or contact them directly for inquiries here .

Remember, efficient rubber compound mixing is crucial for achieving superior results in rubber compounding. Embrace the power of Hydraulic Dispersion Kneaders and discover the difference they can make in your industry.