Introduction

Traditional compression molding has long been a popular method for manufacturing rubber products. However, Microquick Engineers has developed a new approach to rubber molding – Vacuum Type Automatic Compression Rubber Moulding Machines. This innovative technology offers significant advantages over traditional compression molding, addressing common limitations such as air entrapment, material flow issues, and inconsistent part quality. The purpose of this comparison is to highlight the benefits of adopting Vacuum Type Automatic Compression Rubber Moulding Machines in the manufacturing process for precision rubber products.

Traditional Compression Molding

Traditional compression molding is a widely used process for manufacturing rubber products. It involves placing a pre-measured amount of rubber material into a mold cavity, which is then heated and compressed under high pressure to form the desired shape. While this method has been effective for many years, it does have some limitations that can impact product quality and efficiency.

Advantages of Traditional Compression Molding

There are several advantages to using traditional compression molding methods in the production of rubber products. These include:

- Cost-effective: Compression molding is often more affordable than other molding processes, making it an attractive option for manufacturers working with budget constraints.

- Produces strong parts: The compression process creates dense, robust rubber parts that can withstand significant wear and tear.

- Flexibility in design: Compression molding allows for a range of part designs, including complex geometries and intricate details.

Limitations of Traditional Compression Molding

Despite its advantages, traditional compression molding has some inherent limitations that can affect the final product quality and production efficiency. These include:

- Air entrapment: During the compression process, air can become trapped within the rubber material, leading to defects such as voids, air bubbles, or incomplete filling of the mold cavity.

- Material flow issues: In some cases, the rubber material may not flow evenly throughout the mold, resulting in inconsistent part dimensions and properties.

- Inconsistent part quality: Due to factors such as air entrapment and material flow issues, the quality of parts produced using traditional compression molding can vary significantly from one batch to another.

Microquick Engineers has developed a solution to address these limitations through the manufacturing of Vacuum Type Automatic Compression Rubber Moulding Machines. These machines offer a more advanced approach to rubber molding, providing numerous advantages over traditional compression molding methods.

Vacuum Type Automatic Compression Rubber Moulding Machines

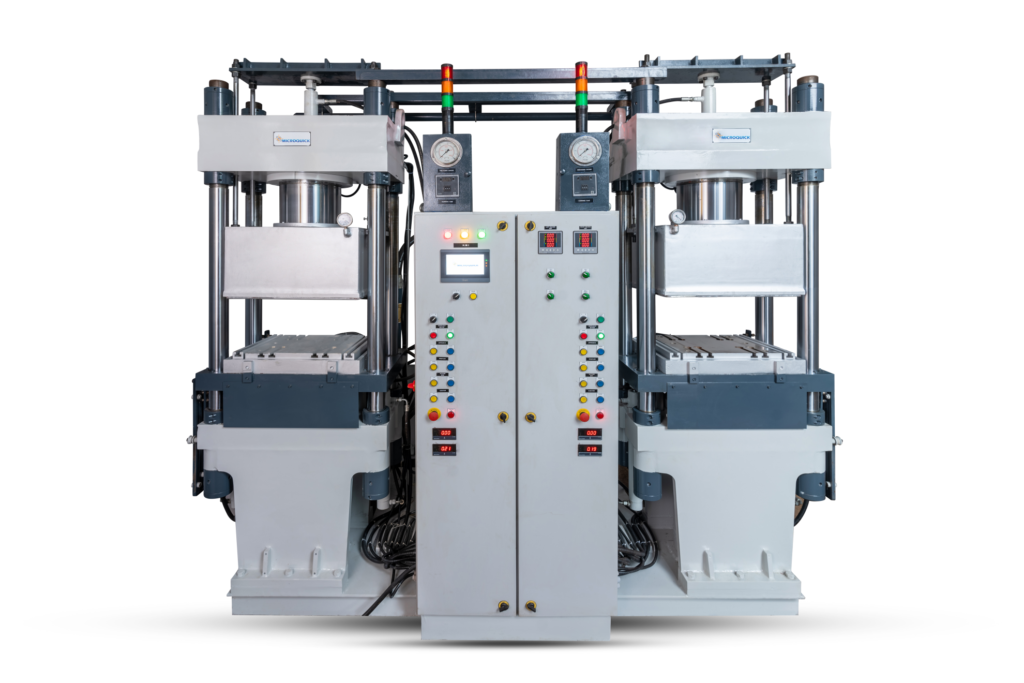

The Vacuum Type Automatic Compression Rubber Moulding Machines manufactured by Microquick Engineers offer a more advanced approach to rubber molding, addressing the limitations of traditional compression molding methods. These machines utilize a vacuum system to eliminate air entrapment and improve material flow, resulting in superior molded product quality, consistency, and efficiency.

Features of Microquick Engineers’ Vacuum Type Automatic Compression Rubber Moulding Machines

Microquick Engineers’ Vacuum Type Automatic Compression Rubber Moulding Machines are designed with several key features to enhance the molding process. These features include:

- High precision: The machines are built with a high level of precision to ensure accurate and consistent molding results.

- Efficient control system: The machines utilize a proportionate hydraulics system for pressure and flow controls, ensuring optimal efficiency during the molding process.

- Uniform heat distribution: The machines are designed to maintain uniform heat distribution throughout the mold, resulting in consistent part quality.

- User-friendly touch screen controls: The machines are equipped with a touch screen interface, allowing operators to easily control and monitor the molding process.

Advantages of Vacuum Type Automatic Compression Rubber Moulding Machines Over Traditional Compression Molding

By addressing the limitations of traditional compression molding, Vacuum Type Automatic Compression Rubber Moulding Machines offer several advantages over their conventional counterparts:

- Superior molded product quality: The vacuum system eliminates air entrapment and improves material flow, resulting in higher quality molded products.

- Elimination of defects: The vacuum system helps to reduce common defects such as air traps, voids, and short shots, ensuring consistently high-quality parts.

- Consistent quality molding: The machines offer more precise process control, leading to consistently high-quality molding results in terms of part dimensions, strength, and surface finish.

- Faster mold filling: The vacuum system allows for faster mold filling, reducing curing time and improving overall efficiency.

- Reduced curing time: The uniform heat distribution and efficient control system help to reduce curing time, speeding up production.

- Faster cycle times: The combination of faster mold filling and reduced curing time leads to significantly faster cycle times compared to traditional compression molding methods.

In conclusion, Vacuum Type Automatic Compression Rubber Moulding Machines offer a more efficient and precise molding process compared to traditional compression molding. By addressing common limitations, these machines deliver superior product quality, consistency, and efficiency, making them an ideal choice for manufacturers of precision rubber products.

Comparison of Traditional Compression Molding and Vacuum Type Automatic Compression Rubber Moulding Machines

When comparing traditional compression molding methods with Vacuum Type Automatic Compression Rubber Moulding Machines manufactured by Microquick Engineers, several key differences become apparent. These differences highlight the advantages of adopting Vacuum Type Automatic Compression Rubber Moulding Machines in the manufacturing process for precision rubber products.

Firstly, the quality of molded products is significantly improved with Vacuum Type Automatic Compression Rubber Moulding Machines. The vacuum system eliminates air entrapment and improves material flow, resulting in higher quality molded products with fewer defects. This is a major advantage over traditional compression molding methods, which can often result in inconsistent part dimensions, strength, and surface finish due to air entrapment and material flow issues.

Another notable difference between the two methods is the speed and efficiency of the molding process. Vacuum Type Automatic Compression Rubber Moulding Machines offer faster mold filling and reduced curing time, resulting in significantly faster cycle times compared to traditional compression molding. This increased efficiency can lead to higher productivity and reduced manufacturing costs for manufacturers of precision rubber products.

Consistency in part dimensions, strength, and surface finish is also enhanced with Vacuum Type Automatic Compression Rubber Moulding Machines. The machines offer more precise process control, leading to consistently high-quality molding results. This is in contrast to traditional compression molding methods, which can often yield inconsistent part quality from one batch to another.

Furthermore, Vacuum Type Automatic Compression Rubber Moulding Machines address material flow issues and the elimination of defects commonly associated with traditional compression molding. The vacuum system helps to reduce common defects such as air traps, voids, and short shots, ensuring consistently high-quality parts. This is a significant advantage for manufacturers looking to produce precision rubber products with minimal defects.

Finally, process control and automation are key features of Vacuum Type Automatic Compression Rubber Moulding Machines. The machines are equipped with user-friendly touch screen controls, allowing operators to easily control and monitor the molding process. This level of automation and control is not typically found in traditional compression molding methods, making Vacuum Type Automatic Compression Rubber Moulding Machines an attractive option for manufacturers of precision rubber products.

In conclusion, Vacuum Type Automatic Compression Rubber Moulding Machines offer a more efficient and precise molding process compared to traditional compression molding. By addressing common limitations, these machines deliver superior product quality, consistency, and efficiency, making them an ideal choice for manufacturers of precision rubber products.

Applications and Industries

Both traditional compression molding and Vacuum Type Automatic Compression Rubber Moulding Machines have their specific applications in various industries. The choice between these two methods largely depends on factors such as production requirements, product design, and material properties. In this section, we will discuss the industries that benefit from each of these molding methods and provide examples of precision rubber products manufactured using Vacuum Type Automatic Compression Rubber Moulding Machines.

Industries that benefit from traditional compression molding include automotive, aerospace, construction, and consumer goods. This method is particularly suited for producing rubber products such as gaskets, seals, and rubber-to-metal bonded components. Despite its limitations, traditional compression molding remains a popular choice for manufacturers due to its cost-effectiveness and flexibility in design.

On the other hand, industries that benefit from Vacuum Type Automatic Compression Rubber Moulding Machines include manufacturers of precision rubber products, such as medical devices, electronics, and high-performance automotive components. Microquick Engineers, a manufacturer of Vacuum Type Automatic Compression Rubber Moulding Machines, has developed this technology to offer significant advantages over traditional compression molding. This method is ideal for producing high-quality, consistent rubber parts with minimal defects and faster cycle times.

Examples of precision rubber products manufactured using Vacuum Type Automatic Compression Rubber Moulding Machines include rubber seals for medical devices, high-performance automotive components, and intricate electronic components. By investing in Vacuum Type Automatic Compression Rubber Moulding Machines, manufacturers can significantly improve the quality, consistency, and efficiency of their production processes, ensuring the best possible end product for their customers.

Conclusion

In this comparison, we have examined the differences between traditional compression molding and Vacuum Type Automatic Compression Rubber Moulding Machines. Traditional compression molding methods, while cost-effective and flexible in design, have limitations such as air entrapment, material flow issues, and inconsistent part quality. On the other hand, Vacuum Type Automatic Compression Rubber Moulding Machines, manufactured by Microquick Engineers, offer significant advantages by addressing these limitations and providing a more efficient and precise molding process.

Investing in Vacuum Type Automatic Compression Rubber Moulding Machines can greatly benefit manufacturers of precision rubber products, as it results in superior molded product quality, elimination of defects, consistent quality molding, faster mold filling, reduced curing time, and faster cycle times. In conclusion, adopting Vacuum Type Automatic Compression Rubber Moulding Machines in the manufacturing process can lead to improved product quality, efficiency, and overall customer satisfaction, making it a valuable investment for manufacturers in the precision rubber products industry.

Discover the Benefits

As we have seen, Vacuum Type Automatic Compression Rubber Moulding Machines offer significant advantages over traditional compression molding methods. These machines address common limitations and provide a more efficient and precise molding process, leading to improved product quality, consistency, and efficiency. If you’re a manufacturer of precision rubber products and are interested in leveraging the benefits of Vacuum Type Automatic Compression Rubber Moulding Machines, we invite you to explore Microquick Engineers’ website for more information and download the comprehensive brochure for an in-depth look at their offerings.

Visit Microquick Engineers’ website | Download the brochure