Hydraulic dispersion kneaders play a vital role in various industries, providing efficient and high-quality mixing solutions. When it comes to choosing the right kneader for your specific needs, comparing different manufacturers is essential. In this blog post, we will explore the advantages and features of Microquick Engineers’ hydraulic dispersion kneaders and how they stack up against competitors.

The importance of selecting the right kneader cannot be overstated. It directly impacts the quality and efficiency of compound production, making it crucial for industries such as automotive, industrial, consumer products, healthcare, electrical, and other rubber industries. Microquick Engineers, a leading manufacturer and exporter of hydraulic dispersion kneaders, offers industry-leading performance, durability, and efficiency.

Their kneaders are equipped with automated continuous hydraulic ram pressure on ingredients, resulting in batch preparation times of 7-12 minutes. With excellent dispersion capabilities and consistent quality compounding, Microquick Engineers’ kneaders are suitable for both small and large-scale production.

In this blog post, we will delve into the specific advantages of Microquick Engineers’ hydraulic dispersion kneaders and compare them to other manufacturers in terms of compound quality, pricing, and overall value for investment. By the end, you will have a clear understanding of why Microquick Engineers’ kneaders are a top choice in the industry.

Are you ready to discover the benefits of hydraulic dispersion kneaders and how Microquick Engineers stands out from the competition? Let’s dive in!

What are Hydraulic Dispersion Kneaders?

Hydraulic Dispersion Kneaders are essential components in the compounding process for various industries. These machines are designed to mix and disperse various ingredients, such as rubber compounds, polymers, and additives, into a homogeneous mixture. They consist of a mixing chamber, rotors, and a hydraulic ram that exerts pressure on the ingredients to create the desired dispersion. This hydraulic pressure ensures efficient mixing and dispersion, resulting in uniform distribution of ingredients throughout the compound.

Purpose and Function

The purpose and function of Hydraulic Dispersion Kneaders are to achieve optimal dispersion of ingredients, improve compound quality, and enhance the overall performance of the final product. By using these kneaders, manufacturers can ensure that the desired properties, such as strength, flexibility, and durability, are uniformly distributed throughout the compound. This is crucial for industries such as automotive, industrial, consumer products, healthcare, electrical, and other rubber industries, where the performance and reliability of the end product are of utmost importance.

Benefits of Hydraulic Dispersion Kneaders

-

Consistent Quality Compounding:

These machines provide excellent dispersion of ingredients, ensuring that each component is uniformly distributed in the compound. This consistency in dispersion leads to improved compound quality and ultimately enhances the performance and durability of the final product. -

Operational Convenience:

Hydraulic Dispersion Kneaders offer operational convenience, with batch preparation times ranging from 7 to 12 minutes. This efficiency allows manufacturers to meet production demands efficiently. -

Durability and Longevity:

Hydraulic Dispersion Kneaders have wear-resistant properties in their mixing chambers and rotors, ensuring durability and longevity. This is particularly important in industries where the kneaders are subjected to high wear and tear, such as rubber industries. -

Energy Efficiency:

These kneaders have low energy consumption, making them an environmentally-friendly choice for manufacturers.

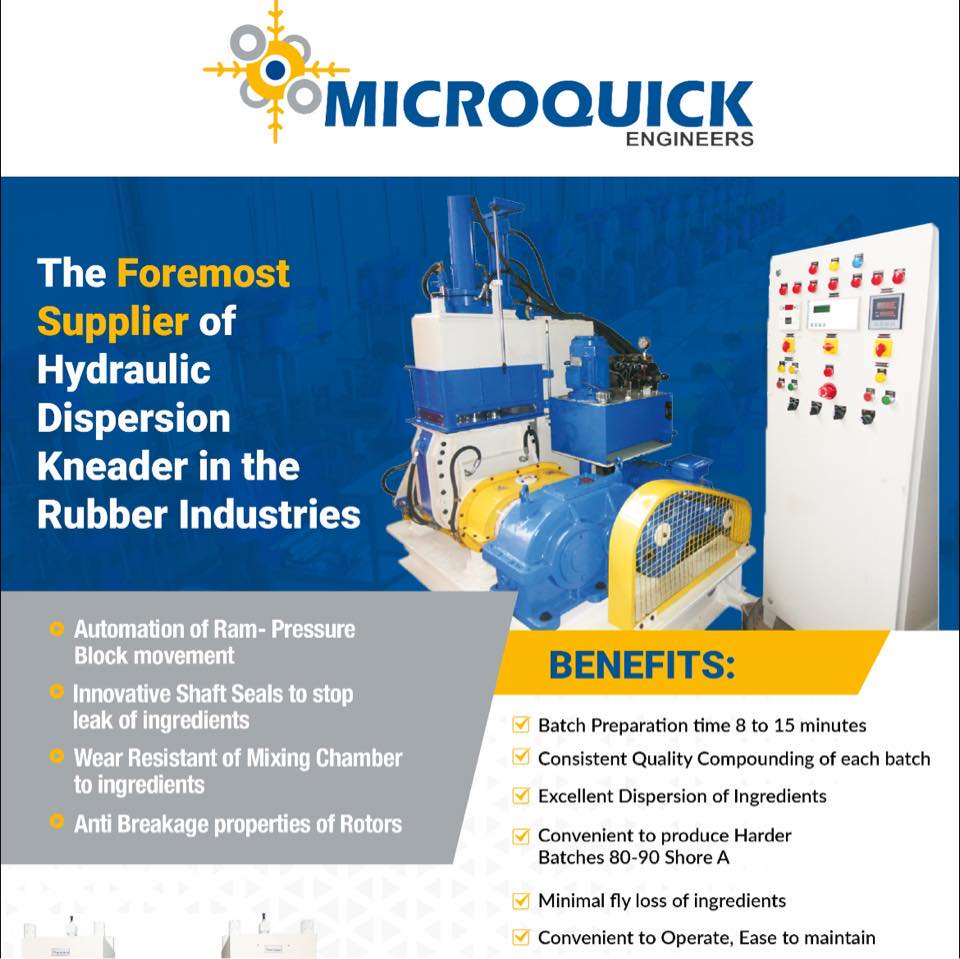

Microquick Engineers: Leading Manufacturer and Exporter of Hydraulic Dispersion Kneaders

Microquick Engineers is a trusted name in the field

of rubber mixing equipment

,

with over 25 years of experience

in the industry. They are known for manufacturing and exporting high-quality Hydraulic Dispersion Kneaders that offer exceptional performance, durability, and efficiency.

Key Features of Microquick Engineers’ Hydraulic Dispersion Kneaders

-

Industry-leading performance:

These kneaders utilize automated continuous hydraulic ram pressure on ingredients, resulting in batch preparation times of 7-12 minutes. This ensures efficient and consistent mixing of ingredients, providing excellent dispersion and high-quality compounding. -

Durability:

The mixing chamber and rotors of Microquick Engineers’ kneaders are designed to be wear-resistant, ensuring long-lasting performance even in demanding industrial environments. This durability translates into cost savings for users. -

Operational advantages:

The kneaders are convenient to use and produce hard batches with ease. The automated hydraulic ram pressure eliminates the need for manual intervention, saving time and ensuring consistent and reliable results. -

Low energy consumption:

Microquick Engineers’ kneaders have low energy consumption, making them an energy-efficient choice for various industries. This helps in reducing operational costs and promoting a greener and more sustainable manufacturing process.

Wide Range of Applications

Microquick Engineers’ Hydraulic Dispersion Kneaders are suitable for a wide range of industries, including:

- Automotive

- Industrial

- Consumer products

- Healthcare

- Electrical

- Other rubber industries

These kneaders offer versatility and can be a valuable asset for businesses operating in different sectors.

Why Choose Microquick Engineers’ Hydraulic Dispersion Kneaders for Superior Compound Quality?

When it comes to compound quality, Microquick Engineers’ Hydraulic Dispersion Kneaders truly stand out from the competition. These kneaders have been designed to achieve exceptional compound quality, surpassing what other manufacturers offer. Let’s take a closer look at why Microquick Engineers’ kneaders are the top choice for achieving superior compound quality.

Dispersion Efficiency and Consistency

One of the key factors that sets Microquick Engineers’ kneaders apart is their dispersion efficiency and consistency. These kneaders are equipped with automated

continuous hydraulic ram

pressure on ingredients, resulting

in batch preparation times

of just 7-12 minutes. This means that the ingredients are mixed thoroughly and uniformly, ensuring that the compound is of the highest quality. The kneaders provide excellent dispersion of ingredients, resulting in a compound that is well-mixed and free from any inconsistencies.

Unique Features and Technologies

But what truly sets Microquick Engineers’ kneaders apart is their unique features and technologies that contribute to superior compound quality. The mixing chamber and rotors of these kneaders have wear resistance properties, ensuring durability and longevity. This means that the kneaders can consistently produce high-quality compound over an extended period of time. Additionally, these kneaders

have low energy consumption

, making them not only efficient but also environmentally friendly.

Versatility for Various Industries

Furthermore, Microquick Engineers’ kneaders are suitable for a wide range of industries, including automotive, industrial, consumer products, healthcare, electrical, and other rubber industries. This versatility allows for the production of high-quality compound for various applications. Whether it’s automotive parts, industrial products, or consumer goods, Microquick Engineers’ kneaders deliver consistent and superior compound quality.

For more information about Microquick Engineers’ Hydraulic Dispersion Kneaders and to explore their range of products, visit their website at https://microquick.us/ .

Investing in Hydraulic Dispersion Kneaders: Pricing, Value, and Benefits

When it comes

to investing in hydraulic dispersion

kneaders, it’s important to consider the pricing and overall value offered by different manufacturers. In this section, we will compare the pricing of Microquick Engineers’ Hydraulic Dispersion Kneaders with its competitors, discuss the overall value for investment provided by Microquick Engineers’ kneaders, and highlight any additional benefits or cost-saving features offered by Microquick Engineers.

Pricing

Microquick Engineers’ Hydraulic Dispersion Kneaders are competitively priced compared to other manufacturers in the market. While some manufacturers offer lower-priced pneumatic mixers, it’s essential to consider the advantages of hydraulic kneaders. Hydraulic kneaders, like the ones manufactured by Microquick Engineers, offer superior performance, durability, and efficiency. They provide automated

continuous hydraulic ram

pressure on ingredients, resulting

in batch preparation times

as low as 7-12 minutes. This not only saves time but also increases productivity, making them a cost-effective choice in the long run.

Overall Value for Investment

Microquick Engineers’ kneaders are known for their excellent dispersion of ingredients

and consistent quality compounding

. The mixing chamber and rotors have wear resistance properties, ensuring durability and reducing maintenance costs. Additionally, Microquick Engineers’ kneaders

have low energy consumption

, making them energy-efficient and cost-effective to operate. This not only helps in reducing operational expenses but also contributes to a greener and more sustainable manufacturing process.

Additional Benefits and Cost-Saving Features

In addition to the competitive pricing and overall value, Microquick Engineers’ Hydraulic Dispersion Kneaders offer several additional benefits and cost-saving features. They are suitable for various industries such as automotive, industrial, consumer products, healthcare, electrical, and other rubber industries. This versatility allows businesses from different sectors to benefit from their efficient mixing capabilities. Furthermore, Microquick Engineers

has over 25 years of experience

in the industry and a high customer satisfaction rate, ensuring reliable after-sales service and support.

When comparing the pricing and overall value for investment of hydraulic dispersion kneaders, Microquick Engineers stands out as a reputable manufacturer. Their kneaders offer industry-leading performance, durability, and efficiency at competitive prices. With additional benefits like low energy consumption and suitability for various industries, investing in Microquick Engineers’ Hydraulic Dispersion Kneaders proves to be a wise choice. So, if you’re looking for a cost-effective and high-quality solution for your rubber mixing needs, consider Microquick Engineers as your trusted partner.

For more information about Microquick Engineers’ Hydraulic Dispersion Kneaders, you can visit their website at [insert CTA URL].

Advantages of Hydraulic Dispersion Kneaders

-

Excellent Dispersion of Ingredients:

Hydraulic dispersion kneaders ensure thorough mixing and dispersion, resulting in consistent and high-quality compounding. This is crucial for industries such as automotive, industrial, consumer products, healthcare, electrical, and other rubber industries where precise and uniform mixing is essential. -

Operational Convenience:

Hydraulic dispersion kneaders have a mixing chamber and rotors designed with wear-resistant properties, ensuring durability and longevity. They can handle even the toughest batches with ease. Additionally, these kneaders have low energy consumption, making them cost-effective and environmentally friendly. -

Unique Selling Points and Innovative Features:

Microquick Engineers’ hydraulic dispersion kneaders offer industry-leading performance, durability, and efficiency. They can prepare batches in as little as 7-12 minutes, thanks to the automated continuous hydraulic ram pressure on ingredients. This saves time and increases productivity. The kneaders are also highly customizable, catering to a wide range of industries and applications. -

Customer Service and Support:

Microquick Engineers prioritize customer satisfaction and provide excellent after-sales service. They offer a video library showcasing their products, allowing potential customers to see the kneaders in action before making a purchase decision.

Factors to Consider When Choosing a Hydraulic Dispersion Kneader Manufacturer

When choosing a hydraulic dispersion kneader manufacturer, there are several

key factors that you should consider

. These factors will greatly impact the selection process and ultimately determine the success of your rubber mixing operations. In this section, we will provide a comprehensive list of these factors and discuss their importance.

Performance and Efficiency

One of the most important factors to consider is the performance and efficiency of the kneaders. You need a manufacturer that offers industry-leading performance, durability, and efficiency. The kneaders should have automated

continuous hydraulic ram

pressure on ingredients, resulting in fast

batch preparation times

. Microquick Engineers, for example, offers kneaders with batch preparation times of 7-12 minutes, ensuring efficient and timely production.

Quality of Compound Production

Another important factor is the quality of compound production. The kneaders should provide excellent dispersion of ingredients

and consistent quality compounding

. Microquick Engineers’

hydraulic dispersion kneaders

are known for their exceptional dispersion capabilities, ensuring that your rubber compounds are thoroughly mixed and of the highest quality.

Durability

Durability is also a key factor to consider. The mixing chamber and rotors should have wear resistance properties, ensuring that the kneaders can withstand the demands of continuous operation. Microquick Engineers’ kneaders are designed with wear-resistant materials, ensuring their longevity and durability.

Energy Consumption

Energy consumption is another factor that should not be overlooked. The kneaders

should have low energy consumption

, helping you reduce operational costs and minimize your environmental impact. Microquick Engineers’ kneaders are designed for energy efficiency, allowing you to achieve optimal performance while minimizing energy consumption.

Experience and Customer Satisfaction

When comparing manufacturers, it’s important to consider their experience and customer satisfaction rate. Microquick Engineers

has over 25 years of experience

in the industry and a high customer satisfaction rate. This demonstrates their expertise and commitment to delivering high-quality products and excellent customer service.

When choosing

a hydraulic dispersion kneader

manufacturer, it’s important to consider factors such as performance, quality of compound production, durability, energy consumption, and the manufacturer’s experience and customer satisfaction rate. By carefully evaluating these factors, you can make an informed decision and select a manufacturer that will meet your specific needs. Microquick Engineers excels in all of these areas, making them a top choice for your hydraulic dispersion kneader needs.

Advancements in Hydraulic Dispersion Kneader Technology

Hydraulic Dispersion Kneaders have come a long way in terms of technology and performance. These machines have revolutionized the rubber mixing process by offering improved efficiency and quality.

One of the key advancements in Hydraulic Dispersion Kneader technology is the incorporation of hydraulic ram pressure on ingredients. This automated feature has significantly reduced batch preparation times, with some kneaders achieving batch preparation in as little as 7-12 minutes. This not only saves valuable production time but also increases overall productivity.

Compared to pneumatic mixers used by most other kneader manufacturers, Hydraulic Dispersion Kneaders have several advantages:

- The hydraulic system provides precise control over the ram pressure, allowing for better dispersion of ingredients and consistent quality compounding.

- The mixing chamber and rotors of these kneaders are designed with wear resistance properties, ensuring durability and longevity. This means that the kneaders can handle heavy-duty mixing and maintain optimal performance over extended periods of use.

Incorporation of Automation and Industry 4.0 Technologies

Another exciting development in the future of rubber mixing technology is the incorporation of automation and Industry 4.0 technologies in Hydraulic Dispersion Kneaders. Automation has already played a significant role in enhancing the efficiency and accuracy of these machines.

With the integration of sensors and advanced control systems, kneaders can now monitor and adjust various parameters in real-time. This ensures consistent and precise mixing, reducing the chances of human error.

Industry 4.0 technologies such as data analytics and connectivity are also being integrated into Hydraulic Dispersion Kneaders. This allows for remote monitoring and control of the machines, enabling manufacturers to optimize their production processes and make data-driven decisions.

By collecting and analyzing data on factors like energy consumption, batch quality, and maintenance requirements, manufacturers can identify areas for improvement and implement proactive measures to enhance overall efficiency and performance.

Importance of Environmentally-Friendly and Sustainable Solutions

As the world becomes increasingly conscious of sustainability, the importance of environmentally-friendly solutions in the future of rubber mixing technology cannot be overstated.

Hydraulic Dispersion Kneaders are already known for their energy efficiency, with low energy consumption compared to other mixing technologies. This not only reduces operational costs but also contributes to a greener and more sustainable manufacturing process.

In addition to energy efficiency, manufacturers are also exploring ways to reduce waste and improve the recyclability of rubber compounds. This includes the development of eco-friendly materials and processes that minimize the environmental impact of rubber mixing.

By adopting sustainable practices, manufacturers can meet the growing demand for environmentally-friendly products and contribute to a more sustainable future.

Potential Future Developments in Hydraulic Dispersion Kneaders

Looking ahead, there are several potential future developments in Hydraulic Dispersion Kneaders that hold promise for the rubber mixing industry.

One area of focus is the continuous improvement of mixing efficiency and performance. Manufacturers are constantly exploring ways to optimize the design and operation of kneaders to achieve even better dispersion and compounding results.

Another potential development is the integration of artificial intelligence (AI) and machine learning algorithms into Hydraulic Dispersion Kneaders. This could enable the machines to learn and adapt to specific mixing requirements, further enhancing their performance and versatility.

AI-powered kneaders could analyze data from various sources, including raw material properties, batch history, and production parameters, to optimize mixing processes and achieve consistent and high-quality results.

In conclusion, the future of rubber mixing technology is bright, with advancements in Hydraulic Dispersion Kneaders driving innovation and efficiency. The incorporation of automation, Industry 4.0 technologies, and sustainable solutions will further enhance the performance and environmental friendliness of these machines. With continuous research and development, we can expect even more exciting developments in the years to come, revolutionizing the rubber mixing industry.

Microquick Engineers: Leading Manufacturer and Exporter of Hydraulic Dispersion Kneaders

Microquick Engineers is a renowned manufacturer and exporter of Hydraulic Dispersion Kneaders. These kneaders offer exceptional performance, durability, and efficiency, making them a preferred choice in various industries. With over 25 years of experience, Microquick Engineers has established a strong reputation for delivering top-quality products.

Benefits of Microquick Engineers’ Hydraulic Dispersion Kneaders

- Automated Continuous Hydraulic Ram Pressure: The kneaders are designed with automated continuous hydraulic ram pressure on ingredients, resulting in batch preparation times of 7-12 minutes. This ensures excellent dispersion of ingredients and consistent quality compounding.

- Convenient and Versatile: These kneaders are not only convenient for producing hard batches but also offer operational convenience. They are valuable assets for various industries such as automotive, industrial, consumer products, healthcare, electrical, and other rubber industries.

- Energy-Efficient and Cost-Effective: Microquick Engineers’ Hydraulic Dispersion Kneaders are known for their low energy consumption, making them energy-efficient and cost-effective.

- Durable and Long-Lasting: The mixing chamber and rotors of these kneaders are designed with wear resistance properties, ensuring durability and longevity.

To learn more about Microquick Engineers’ Hydraulic Dispersion Kneaders and explore their video library showcasing their products, visit their website at https://microquick.us/ . They also provide valuable resources and insights on optimizing the performance and efficiency of dispersion mixers at https://microquick.us/tag/adjust/ .

Whether you’re looking to enhance the quality of your automotive rubber parts or understand the importance of energy efficiency in rubber processing equipment , Microquick Engineers’ website provides a wealth of information to help you make informed decisions.

Take the next step towards improving your rubber processing operations by considering the key factors when choosing a hydraulic dispersion kneader manufacturer. Visit https://microquick.us/5-key-factors-to-consider-when-choosing-a-hydraulic-dispersion-kneader-manufacturer/ to gain valuable insights and make an informed choice. Microquick Engineers is here to support you in achieving efficient and high-quality rubber compounding processes.