Introduction

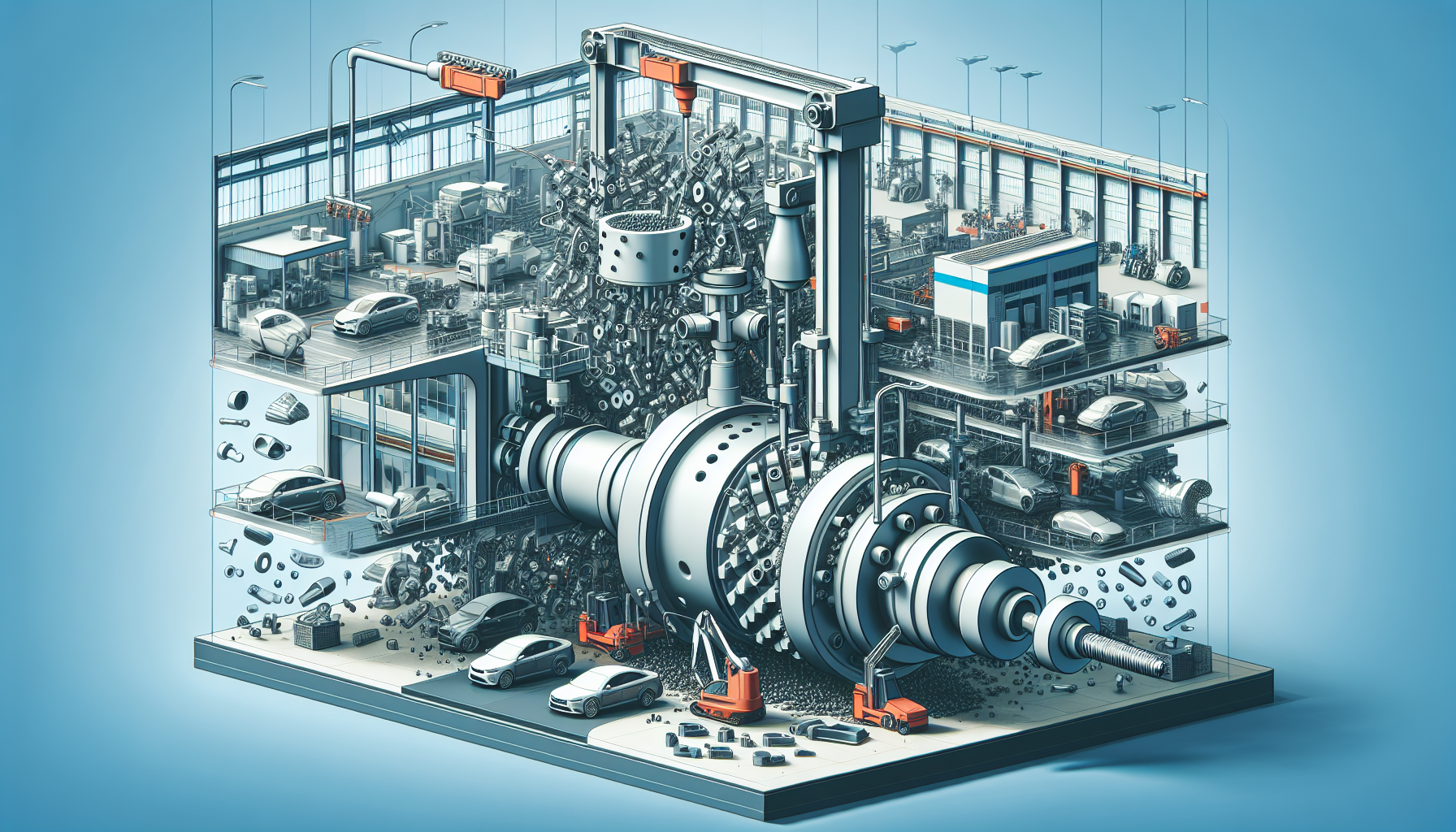

Hydraulic Dispersion Kneaders play a vital role in the automotive industry, where high-quality compounding is crucial for manufacturing durable and efficient auto parts. These advanced machines use hydraulic pressure to ensure excellent dispersion and consistent quality in the production process. As the demand for superior auto parts continues to grow, Hydraulic Dispersion Kneaders have become indispensable for producing the required compound with precision and efficiency.

Key Features of Hydraulic Dispersion Kneaders

Hydraulic Dispersion Kneaders offer a range of innovative features that make them an ideal choice for manufacturing high-quality compounds for auto parts. Some of these key features include:

-

Automated continuous hydraulic compression: This feature ensures uniform pressure on the ingredients, leading to excellent quality compounding and the ability to manufacture the required compound for auto parts with precision.

-

Excellent dispersion of ingredients: The kneaders are designed to provide optimal dispersion of various ingredients, ensuring a homogeneous and consistent mixture in the compounding process.

-

Consistent quality compounding: With their advanced technology, Hydraulic Dispersion Kneaders maintain a high level of consistency in the quality of compounds produced, meeting the stringent requirements of the automotive industry.

-

Innovative shaft seals with lubrication passage: These kneaders come equipped with state-of-the-art shaft seals that prevent ingredient leaks and ensure smooth operation.

-

Low energy consumption: Hydraulic Dispersion Kneaders are designed to consume minimal energy, making them an environmentally friendly and cost-effective solution for the automotive industry.

-

Operator-friendly design and compact size: The ergonomic design of these kneaders allows for easy operation, while their compact size ensures they fit seamlessly into any production facility.

These key features make Hydraulic Dispersion Kneaders the preferred choice for automotive industry professionals looking to optimize their compounding processes and enhance the quality of their auto parts.

Advantages of Using Hydraulic Dispersion Kneaders in the Automotive Industry

Hydraulic Dispersion Kneaders have become essential in the automotive industry due to their ability to manufacture the required compound for auto parts with precision and efficiency. Let’s explore the advantages they offer:

Excellent quality compounding for automotive parts: Hydraulic Dispersion Kneaders ensure a high level of quality in the compounding process, resulting in durable and reliable automotive parts that meet industry standards.

Faster production and reduced batch preparation time: These kneaders are designed for quick and efficient production, reducing batch preparation time and accelerating the overall manufacturing process.

Automated consistent quality batch preparation: The advanced technology used in Hydraulic Dispersion Kneaders allows for automated and consistent batch preparation, ensuring uniform quality across all manufactured auto parts.

Improved wear resistance of mixing chamber and rotors: The design of these kneaders provides enhanced wear resistance for the mixing chamber and rotors, prolonging the equipment’s lifespan and reducing maintenance costs.

Enhanced stop leak and fly of ingredients performance: Innovative shaft seals with lubrication passage in Hydraulic Dispersion Kneaders help prevent ingredient leaks and enhance the performance of stop leak and fly of ingredients, ensuring a smooth and efficient compounding process.

Value for investment: With their high-quality compounding capabilities, faster production times, and automated consistent quality batch preparation, Hydraulic Dispersion Kneaders provide a valuable return on investment for automotive industry professionals seeking to optimize their manufacturing processes.

In conclusion, Hydraulic Dispersion Kneaders offer numerous advantages for the automotive industry, making them an indispensable tool for producing high-quality compounds and auto parts that meet the ever-evolving demands of this competitive market.

Applications of Hydraulic Dispersion Kneaders in the Automotive Industry

Hydraulic Dispersion Kneaders have become indispensable in the automotive industry due to their ability to manufacture the required compound for auto parts with precision and efficiency. Some of the key applications of these machines in the automotive industry include:

Manufacturing of tires and rubber components: Through hydraulic dispersion kneader technology, the automotive industry can produce high-quality tires and rubber components that meet strict performance and durability standards. These kneaders ensure excellent dispersion of ingredients, leading to consistent and reliable compounds used in tire and rubber component manufacturing.

Production of plastic auto parts: Hydraulic Dispersion Kneaders are also utilized in the production of plastic auto parts, such as interior trim and dashboard components. These kneaders offer a precise and efficient compounding process, ensuring consistent quality and performance in the final product.

Creation of composite materials for lightweight vehicles: The automotive industry is increasingly focusing on lightweight materials to improve fuel efficiency and reduce emissions. Hydraulic Dispersion Kneaders play a crucial role in the development of composite materials, as they provide excellent dispersion and consistent quality in the compounding process. This results in high-performance composite materials that contribute to lightweight vehicle designs.

In summary, Hydraulic Dispersion Kneaders have a wide range of applications in the automotive industry, ensuring the production of high-quality compounds and auto parts that meet the demands of this competitive market.

Microquick Engineers: A Trusted Manufacturer and Exporter

With over 25 years of experience in the industry, Microquick Engineers has established itself as a trusted manufacturer and exporter of Hydraulic Dispersion Kneaders. Serving a diverse range of industries, including automotive, industrial, consumer products, healthcare, and electrical, Microquick Engineers has developed a reputation for delivering high-quality and reliable compounding solutions.

One of the unique selling points of Microquick Engineers’ Hydraulic Dispersion Kneaders is their ability to manufacture the required compound for auto parts with precision and efficiency. This is achieved through their advanced technology and innovative design, ensuring excellent dispersion and consistent quality compounding. As a result, automotive industry professionals can rely on Microquick Engineers to provide the optimal compounding solutions for their manufacturing processes.

In conclusion, Microquick Engineers is a trusted name in the manufacturing and exporting of Hydraulic Dispersion Kneaders, offering a range of state-of-the-art solutions that cater to the specific needs of the automotive industry and beyond.

Conclusion

In conclusion, Hydraulic Dispersion Kneaders have become an integral part of the automotive industry, playing a critical role in manufacturing high-quality compounds for auto parts with precision and efficiency. As the demand for superior auto parts continues to grow, these advanced machines have proven to be indispensable in meeting the industry’s stringent requirements.

Microquick Engineers, with their extensive experience and innovative solutions, have demonstrated their commitment to providing the automotive industry with advanced compounding technology. Their state-of-the-art Hydraulic Dispersion Kneaders are designed to meet the specific needs of automotive professionals, ensuring excellent dispersion and consistent quality in the manufacturing process. In a competitive market that demands innovation and efficiency, Microquick Engineers stands out as a trusted provider of reliable and high-performance Hydraulic Dispersion Kneaders.

Discover Microquick’s Solutions

Now that you’ve learned about the advantages of Hydraulic Dispersion Kneaders in the automotive industry, it’s time to explore how Microquick Engineers can provide you with tailored solutions for your compounding needs. Visit Microquick Engineers’ website to learn more about their innovative products and services. Don’t forget to download the company brochure for an in-depth look at their product offerings. Contact Microquick Engineers today and take the first step towards optimizing your automotive compounding processes with their advanced Hydraulic Dispersion Kneaders.