Rubber Machinery Manufacturing and Exporting

Rubber machinery manufacturing and exporting are pivotal in driving innovation and enhancing productivity in the rubber industry. As the demand for high-quality rubber goods continues to rise, the need for reliable and efficient rubber machinery has become increasingly paramount. Specialized manufacturers and exporters are dedicated to providing cutting-edge equipment and technology to meet the evolving needs of the industry. These entities play a crucial role in developing advanced machinery for processes such as compounding, mixing, extrusion, molding, and vulcanization, contributing to the optimization of production processes and the creation of superior rubber products. This introduction will delve into the world of rubber machinery manufacturing and exporting, exploring the key aspects of this industry, the latest technological advancements, and the impact of these developments on the global rubber market. By examining the critical role played by rubber machinery manufacturers and exporters, we aim to gain a comprehensive understanding of their significance in shaping the future of the rubber industry.

Types of Rubber Machinery

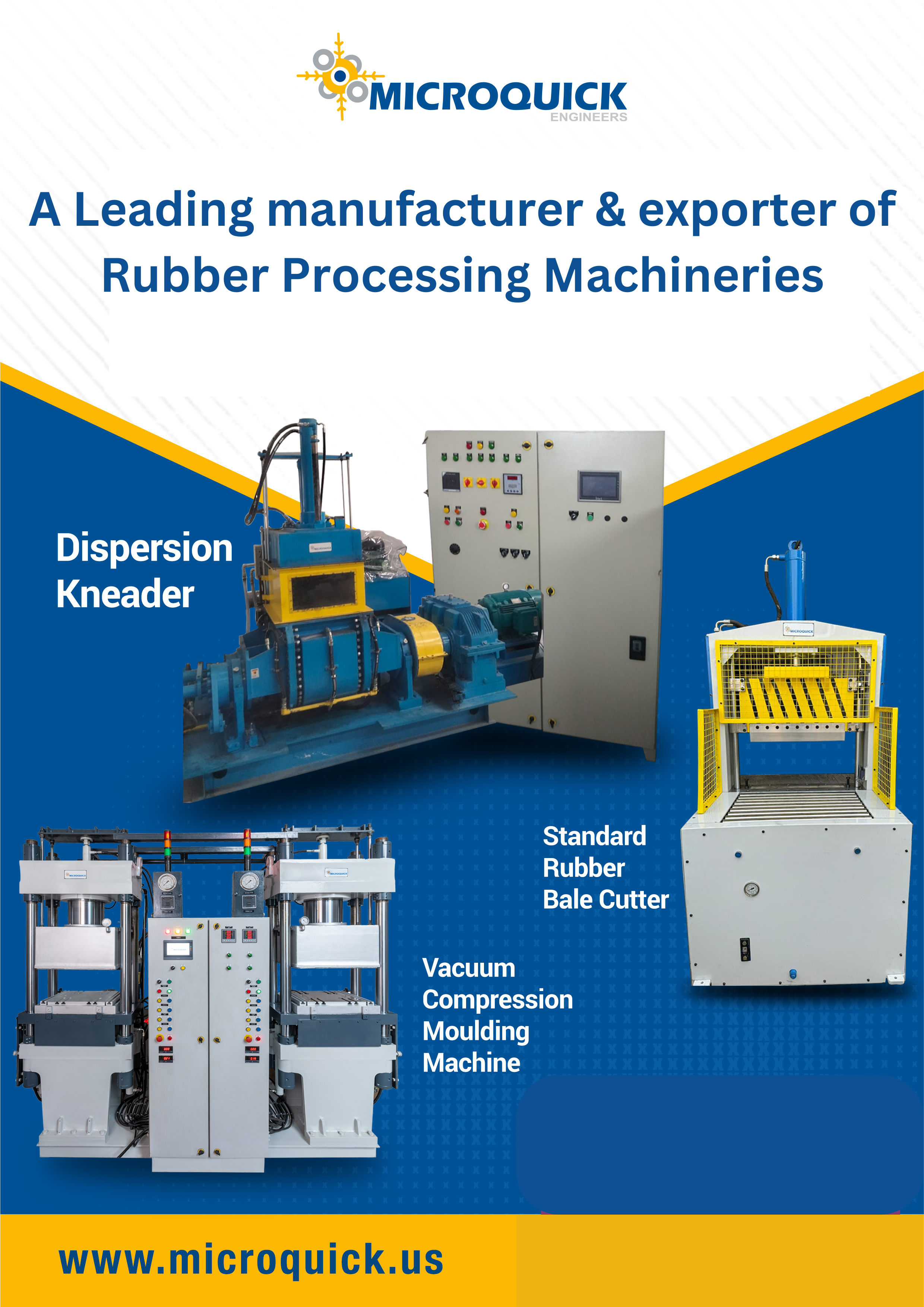

When it comes to the rubber industry, the machinery used plays a crucial role in the production process. From mixing to cutting, various types of machinery are essential for the efficient manufacturing of rubber products. In this section, we will explore the different types of rubber machinery, including rubber mixers, rubber bale cutters, and other essential machinery. Additionally, we will discuss the key manufacturers and suppliers in the rubber machinery industry.

Rubber Mixer Rubber mixers are fundamental

in the rubber manufacturing process

. These machines are designed to blend rubber compounds with various additives to create the desired rubber material. The mixing process is critical for achieving uniformity and consistency in the rubber compound, which directly impacts the quality of the final rubber products. There are different types of rubber mixers, including internal mixers and open mill mixers, each serving specific purposes in the production cycle.

Rubber Bale Cutter Rubber bale cutters are used to cut large bales of rubber into smaller, more manageable pieces. This initial processing step is essential for preparing the rubber material for further processing in the production line. By reducing the size of the rubber bales, the material becomes easier to handle and feed into subsequent machinery. Rubber bale cutters are available in various configurations, including manual, semi-automatic, and fully automatic models, catering to different production requirements.

Other Essential Rubber Machinery In addition to rubber mixers and bale cutters, several other types of machinery are integral to the rubber manufacturing process. This includes extruders for shaping rubber into specific profiles, vulcanizing presses for curing rubber products, and molding machines for creating intricate rubber components. Each of these machines plays a vital role in transforming raw rubber materials into a wide range of finished products, such as tires, seals, gaskets, and industrial rubber components.

Rubber Machinery Manufacturers & Suppliers The market for rubber machinery is served by a diverse range of manufacturers and suppliers. These companies specialize in producing high-quality machinery tailored to the unique requirements of the rubber industry. Leading manufacturers often offer a comprehensive range of machinery, including custom solutions for specific applications. Additionally, suppliers play a crucial role in providing essential spare parts, technical support, and maintenance services to ensure the optimal performance and longevity of rubber machinery.

The diverse array of rubber machinery, including mixers, bale cutters, and other essential equipment, forms the backbone of the rubber manufacturing industry. The seamless integration of these machines in the production process is essential for achieving efficiency, precision, and consistency in the production of rubber products. Furthermore, the collaboration between manufacturers and suppliers ensures that the industry has access to cutting-edge machinery and reliable support, driving innovation and advancement in the rubber manufacturing sector. In this section, we have delved into the critical role of rubber machinery in the manufacturing process, highlighting the significance of each type of machinery and the contributions of manufacturers and suppliers to the industry’s success.

Choosing the Right Rubber Machinery

Rubber machinery plays a crucial role in the manufacturing process of rubber products. Selecting the right machinery is essential for ensuring efficiency, quality, and cost-effectiveness. In this section, we will explore

the factors to consider when choosing

rubber machinery and the customization options available. When selecting rubber machinery, several factors need to be carefully considered to ensure that the chosen equipment aligns with the specific production requirements and business goals.

-

Production Capacity

- The machinery’s production capacity should match the anticipated production volume.

- Assess current and future production needs to avoid investing in inadequate machinery.

-

Technology and Innovation

- Keeping abreast of the latest technological advancements in rubber machinery is crucial.

- Up-to-date technology can enhance productivity, improve product quality, and reduce operational costs.

-

Quality and Durability

- The durability and quality of the machinery are paramount.

- Investing in high-quality equipment may require a larger initial investment but can lead to long-term cost savings.

-

Energy Efficiency

- Energy-efficient machinery can significantly reduce operational costs and environmental impact.

- Consider the energy consumption and efficiency of the machinery to make an informed decision.

-

Maintenance and Support

- Assess the availability of maintenance services and technical support.

- Opt for machinery from reputable manufacturers with a strong support network.

Customization options for rubber machinery can provide businesses with the flexibility to tailor equipment to their specific production needs and processes.

-

Custom Tooling

- Manufacturers offer custom tooling options, allowing businesses to create unique rubber products.

-

Automation and Control Systems

- Machinery customization often includes the integration of advanced automation and control systems tailored to the specific production processes.

-

Material Handling and Feeding Systems

- Customizing material handling and feeding systems can optimize the production process.

-

Safety Features

- Customization options extend to safety features, allowing businesses to incorporate additional safety measures.

-

Integration with Existing Systems

- Customization options can include seamless integration of new machinery with the current infrastructure.

Choosing the right rubber machinery involves a comprehensive assessment of various factors and an exploration of customization options. By carefully considering production needs, technological advancements, quality, and customization possibilities, businesses can make informed decisions that align with their operational requirements and long-term objectives.

Top Qualities of a Reliable Rubber Machinery Manufacturer

When it comes to choosing a rubber machinery manufacturer, there are several key qualities that can indicate reliability and professionalism. In this blog post, we will explore the top qualities to look for when selecting a manufacturer for your rubber machinery needs. One of the most crucial qualities to consider when choosing a rubber machinery manufacturer is their experience and expertise in the industry. A reliable manufacturer should have a proven track record of designing and producing high-quality rubber machinery. Look for a manufacturer that has been in the industry for a significant amount of time and has a deep understanding of the complexities of rubber processing. Their experience and expertise will ensure that they can provide you with the best solutions for your specific needs. Another essential quality to consider is the manufacturer’s commitment to quality standards. The quality of the rubber machinery you invest in can have a significant impact on the efficiency and effectiveness of your operations. A reliable manufacturer should adhere to strict quality control measures throughout the manufacturing process. Look for certifications and accreditations that demonstrate their commitment to maintaining high standards. Additionally, inquire about the materials and components used in their machinery to ensure durability and longevity. In addition to the quality of their products, the level of customer support offered by a manufacturer is a crucial factor to consider. A reliable manufacturer should prioritize customer satisfaction and provide excellent support throughout the entire process, from initial inquiries to after-sales support. Look for a manufacturer that is responsive, transparent, and willing to address any concerns or questions you may have. Good customer support can make a significant difference in your overall experience and satisfaction with the machinery you purchase. When searching for a reliable rubber machinery manufacturer, it is essential to consider their experience and expertise, commitment to quality standards, and level of customer support. By prioritizing these qualities in your selection process, you can ensure that you partner with a manufacturer who can provide you with high-quality, reliable rubber machinery to meet your specific needs.

Conclusion

The advancements in hydraulic compression technology for rubber manufacturing, as highlighted on the webpage at. Microquick , offer significant benefits such as precise control, improved product quality, and increased efficiency. This information is invaluable for individuals and companies involved in the rubber industry, seeking to enhance their manufacturing processes. With Microquick Engineers’ expertise and experience in the industry, the webpage provides valuable insights into the latest developments in rubber machinery. For those looking to stay at the forefront of rubber manufacturing technology, exploring the products offered by Microquick, including Hydraulic Dispersion Kneaders and Compression Moulding Machines, is essential. To explore the latest advancements in rubber machinery, visit. Microquick .